EUO CrateImprove the efficiency and operation

of factory automation.

of factory automation.

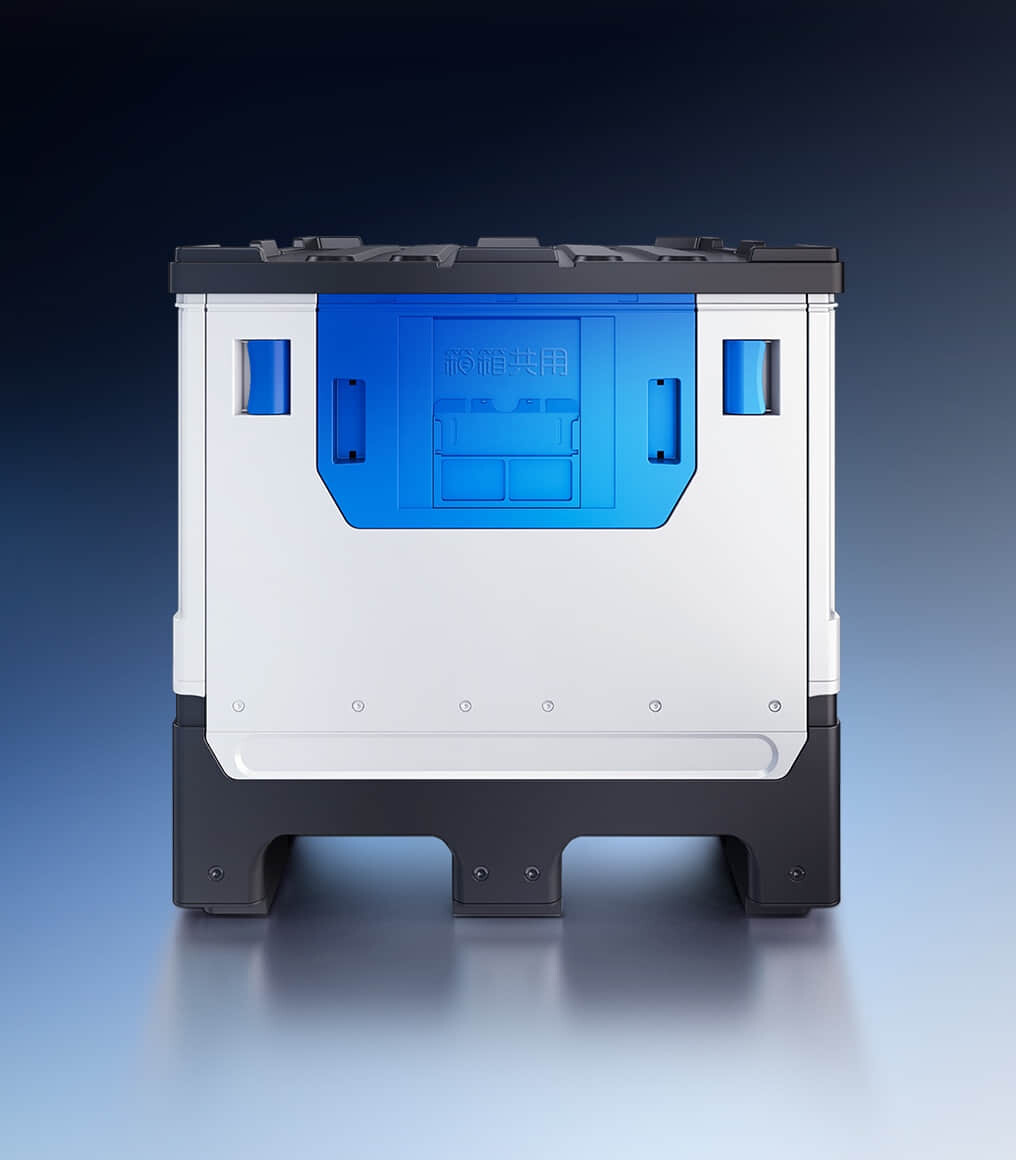

Sleeve PackLightweight and strong durable,

easy to load and unload.

easy to load and unload.

LWFLCEasier distribution of

express parcels and post.

express parcels and post.

KF975Double smooth folding container,

compatible with other FLC.

compatible with other FLC.

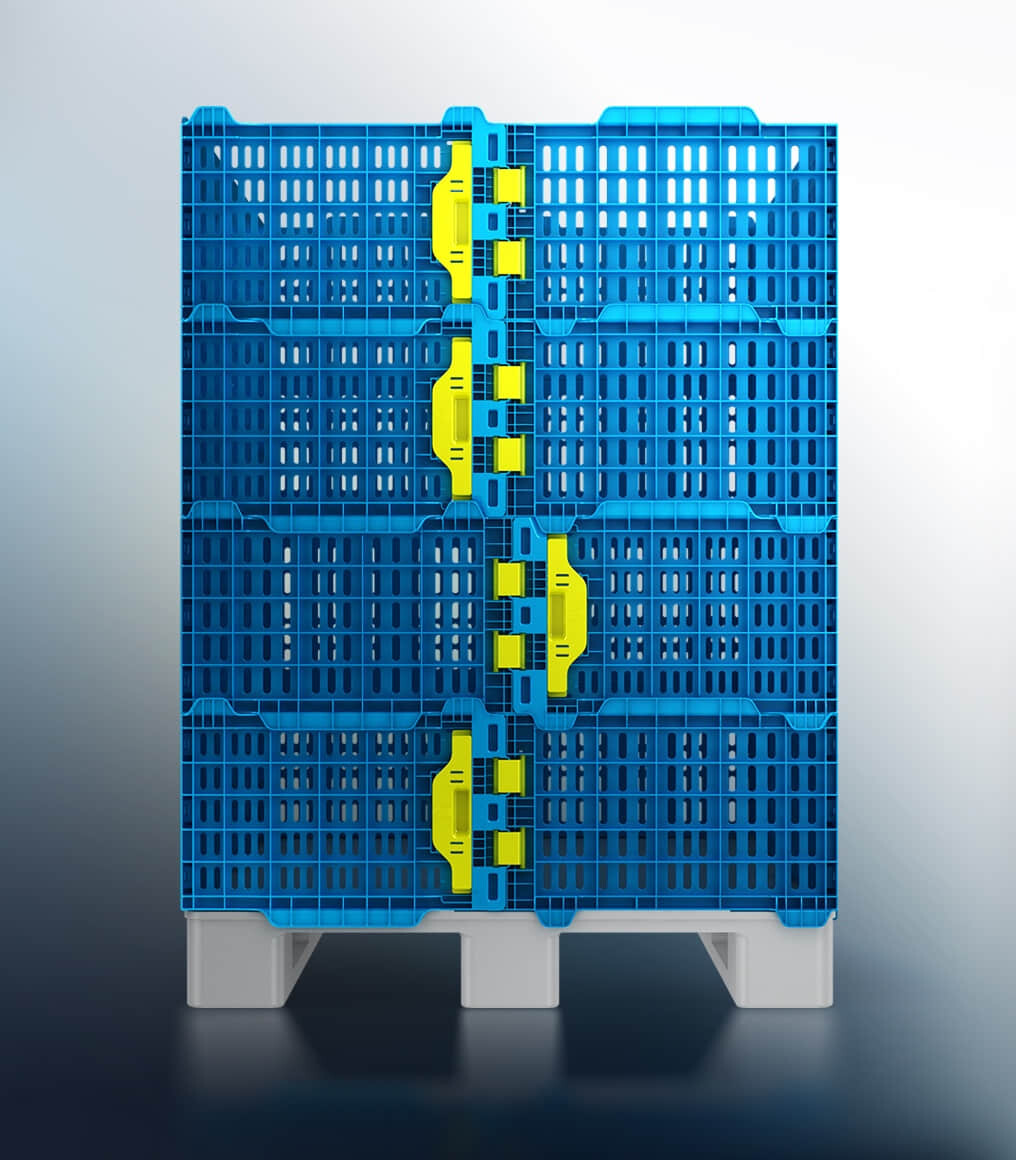

Pallet CollarEase to transform plastic or

wooden pallets into folding container.

wooden pallets into folding container.

Efficient and universal

standard packaging.The standard folding containers independently developed by HOREN provide the ideal solution for highly unstandardized auto parts packaging. This allows seamless collaboration between factories, production control, and third-party component suppliers, helping to enhance internal and external logistics coordination and improve operational efficiency. HOREN auto parts packaging are also well-suited for automated use scenarios.

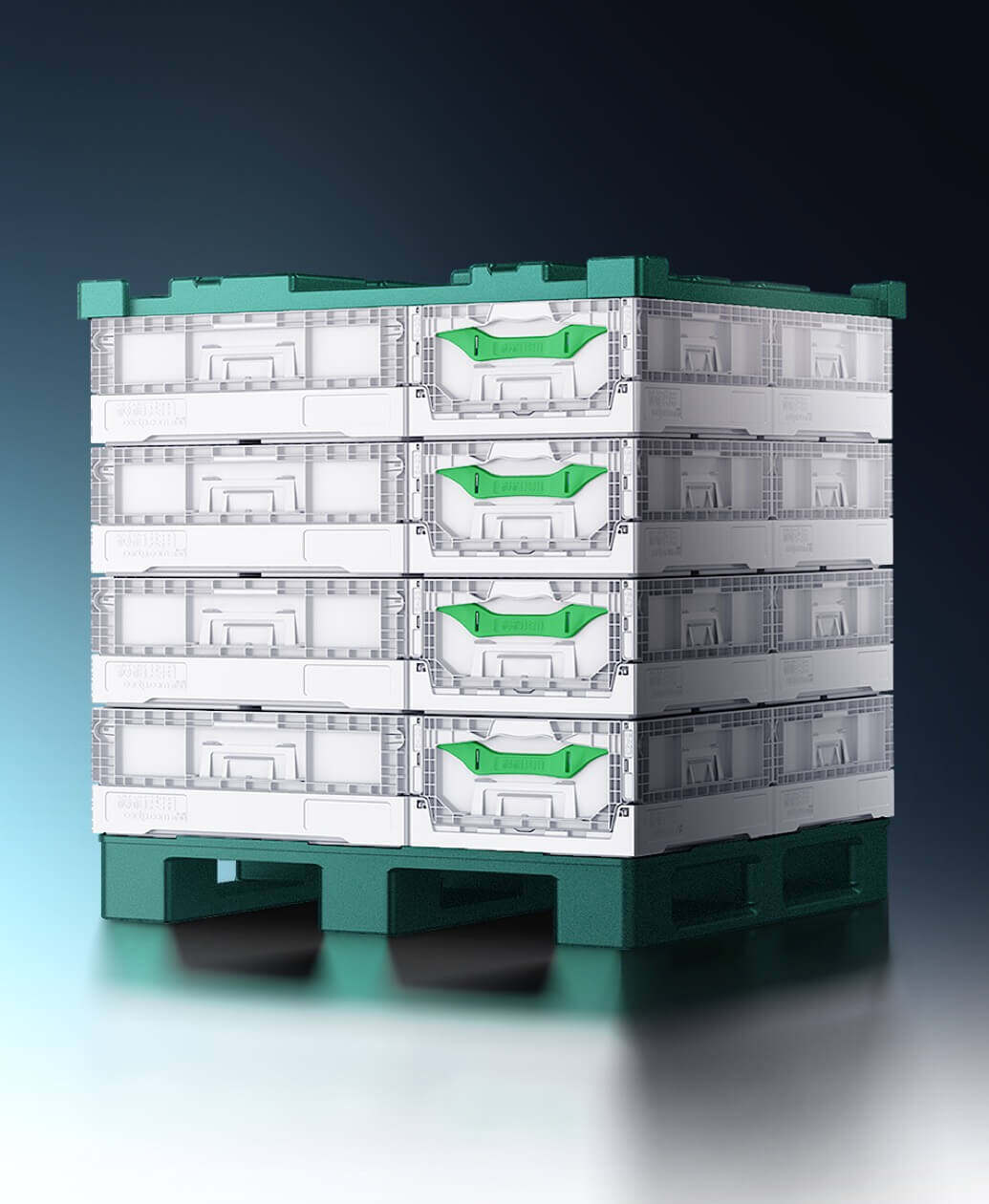

Advantages of the

foldable and returnable

packaging.Folding ratio up to 7:1. We provide customers with a variety of foldable containers for auto parts - from 600*400mm to standard 1200*1000mm and non-standard sizes. A folding ratio of up to 7:1 helps reduce the load volume of return transport by 80%, greatly optimizing operation costs. Compatible with the international standard pallet (1200X1000mm), they can be flexibly combined and transported with higher efficiency, both departure and return.

Reusable transport packaging(RTP) reduce the emission of greenhouse gases and other harmful gases, and make our society greener and more sustainable.

Integrated solution from

containers to liners.Our professional design team provides customizable dunnages solutions to protect products from bumps and impacts during transport. These liners are perfectly tailored to a wide array of shapes, ensuring product safety during long-distance transportation.

CoRTPAI + IP, New era of smart packaging.

Learn more

Our clients

All the data on this website is provided by HOREN unless otherwise stated.

*Full load: Only when the liquid density ≤ 1.35g/cm³.

*High reliability test: All tests are tested at HOREN’s standard labs in simulation of the conditions required by ISTA and ASTM.

*Traditional non-foldable IBC: Non-foldable plastic IBC tanks in general on the market with dimensions of 1200x1000x1145mm.

*Regular plastic foldable IBC: IBCs on the market under Asian and European standards and with dimensions of 1200x1000x1140mm and volume of around 1000L. Thus IBC OF330, with a volume of 1249L, is about 25% larger.

*Two-thirds: The volume of a folded IBC is approximately 1/3 of that when unfolded. So compared with a non-foldable container of the same size, 2/3 of the storage space is saved for return transport.

*Three-quarters: The volume of a folded IBC OF330 is approximately 1/4 of that when unfolded. So compared with a non-foldable container of the same size, 3/4 of the storage space is saved for return transport.

*Service life of up to 10 years: Measured in accordance with the limited conditions in HOREN’s standard labs.

*TE pin: Available upon request and purchase.

*Heater pad: Available upon request and purchase.

*7.6:1: The ratio of the volume of an erected KingKong RPC to that when folded is approximately 7.6:1.

*31%: Obtained upon measurement of multiple products under the same conditions of compression test in HOREN’s standard labs.

*No Crate Change: Goods stored in HOREN’s crates can be directly transported from farm or place of origin to market for display and sale, without the need to change to new crates.

*0.1%: In HOREN’s standard lab environment, 1000kg of 300,000-cP viscous liquid, after being discharging, leaves residues weighing <1kg.

*Hands-free: After RRS and liner are installed, no more manual operation is needed during the discharge process.

*Folding ratio 3:1: The ratio of the volume of an erected FLC KF975 to that when folded is approximately 3:1.