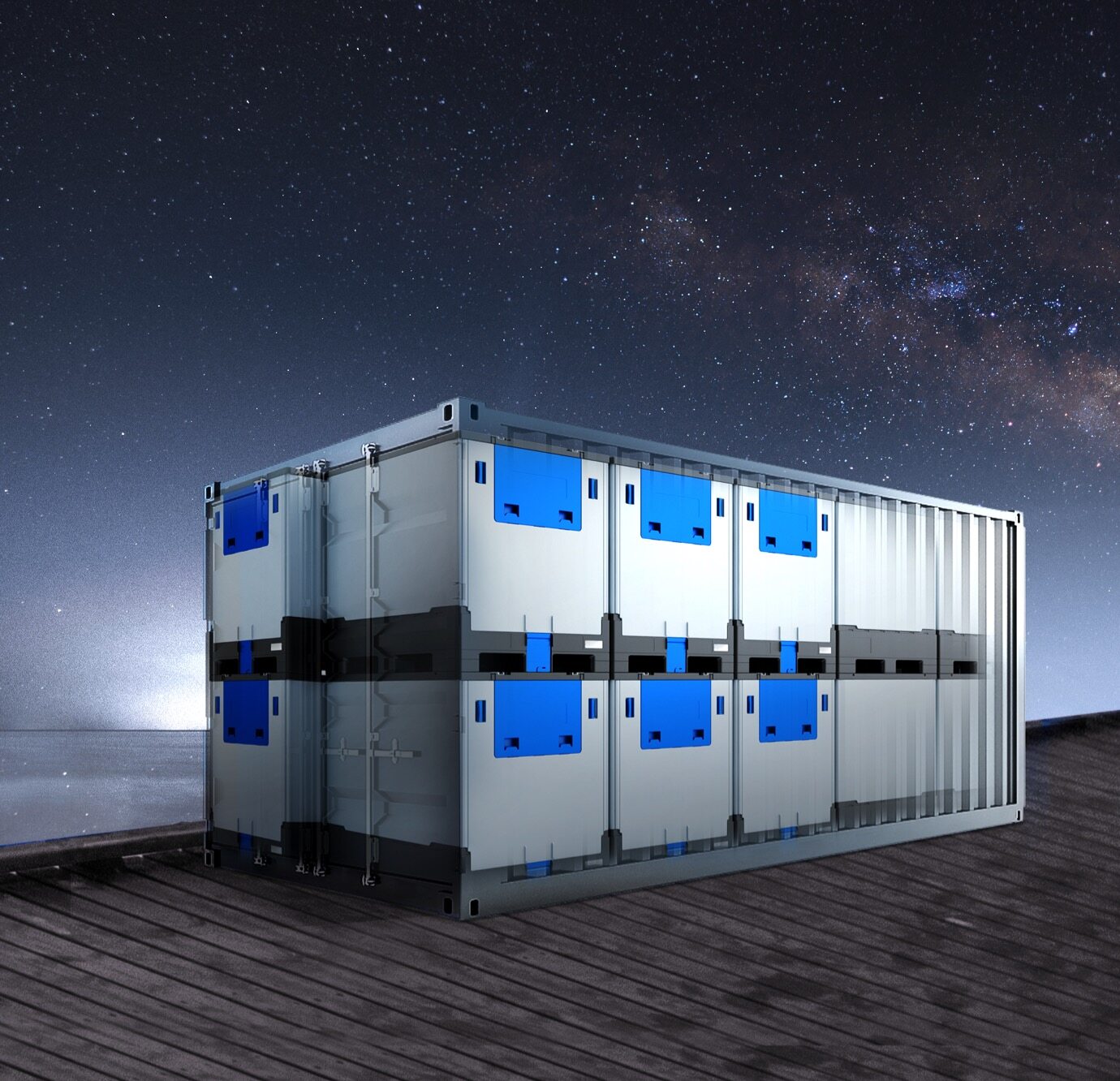

Space saved.

Costs saved.

Space saved.

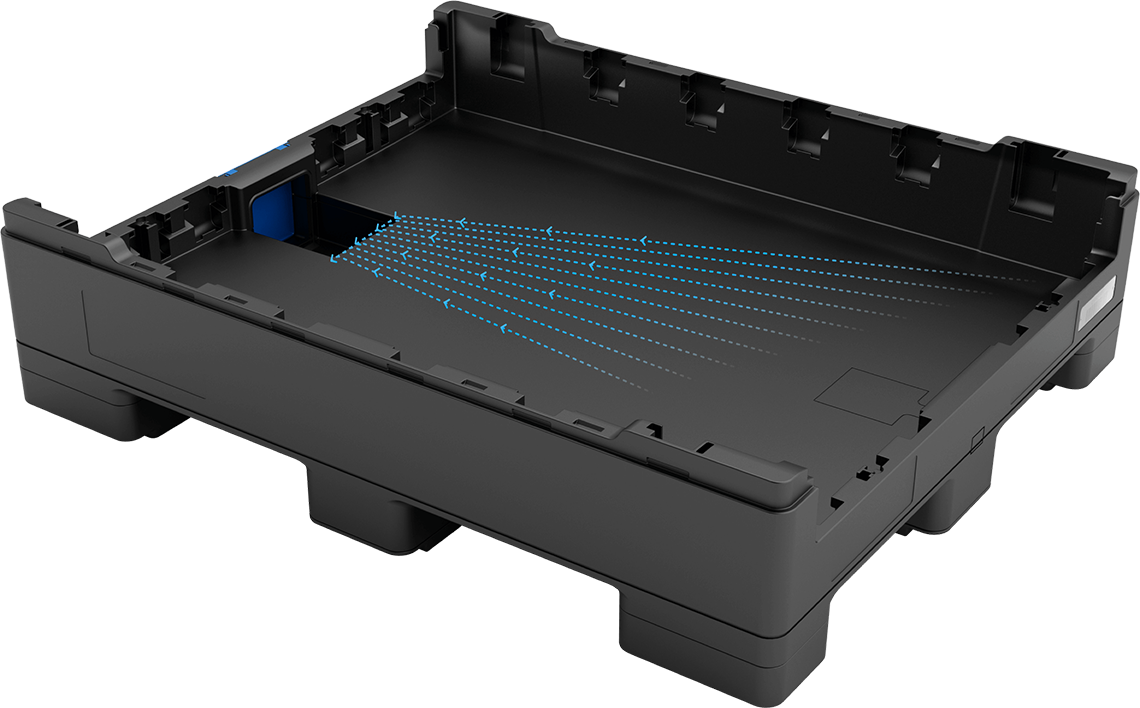

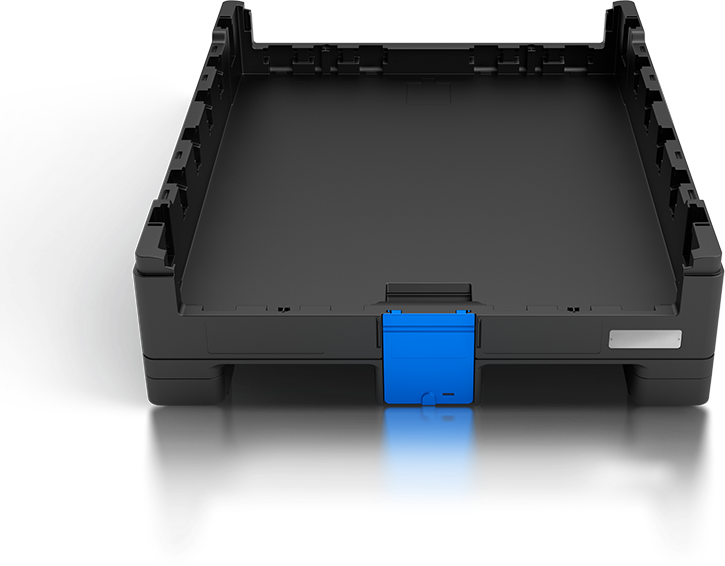

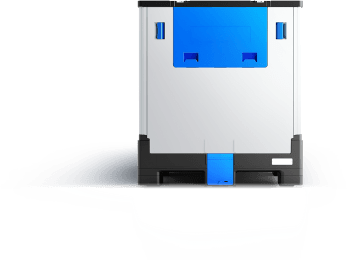

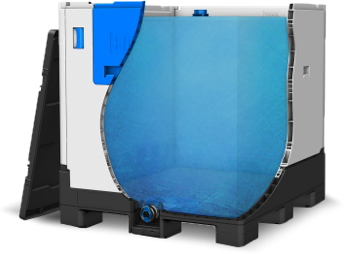

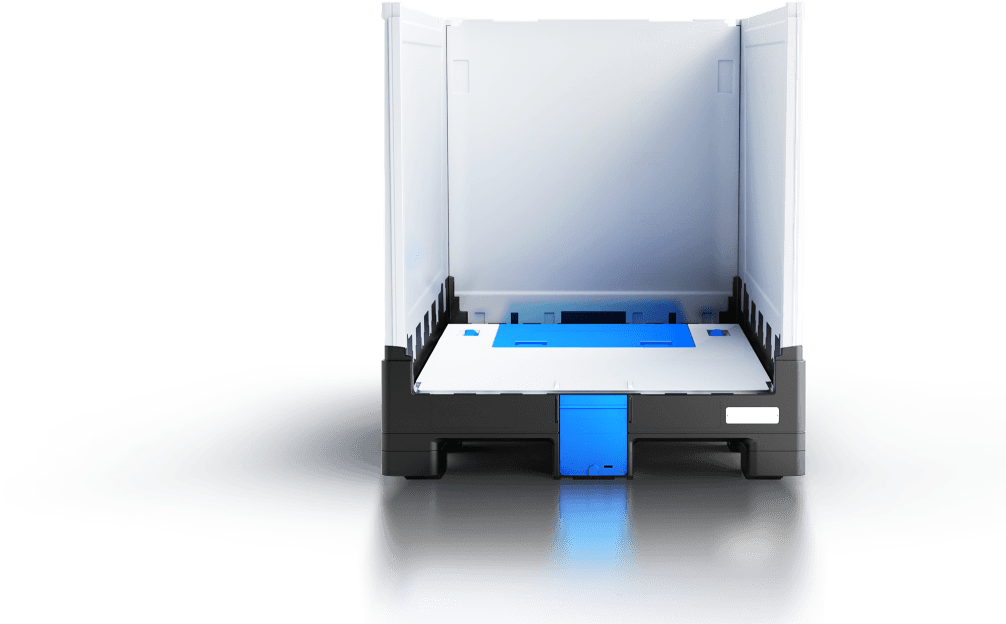

Costs saved.IF1040’ folding ratio is beyond the market standard. For example, a 9.6-meter truck can only load no more than 36 conventional non-foldable IBC Tanks at one time, but up to 136 folded IF1040 containers, greatly reducing supply chain costs.

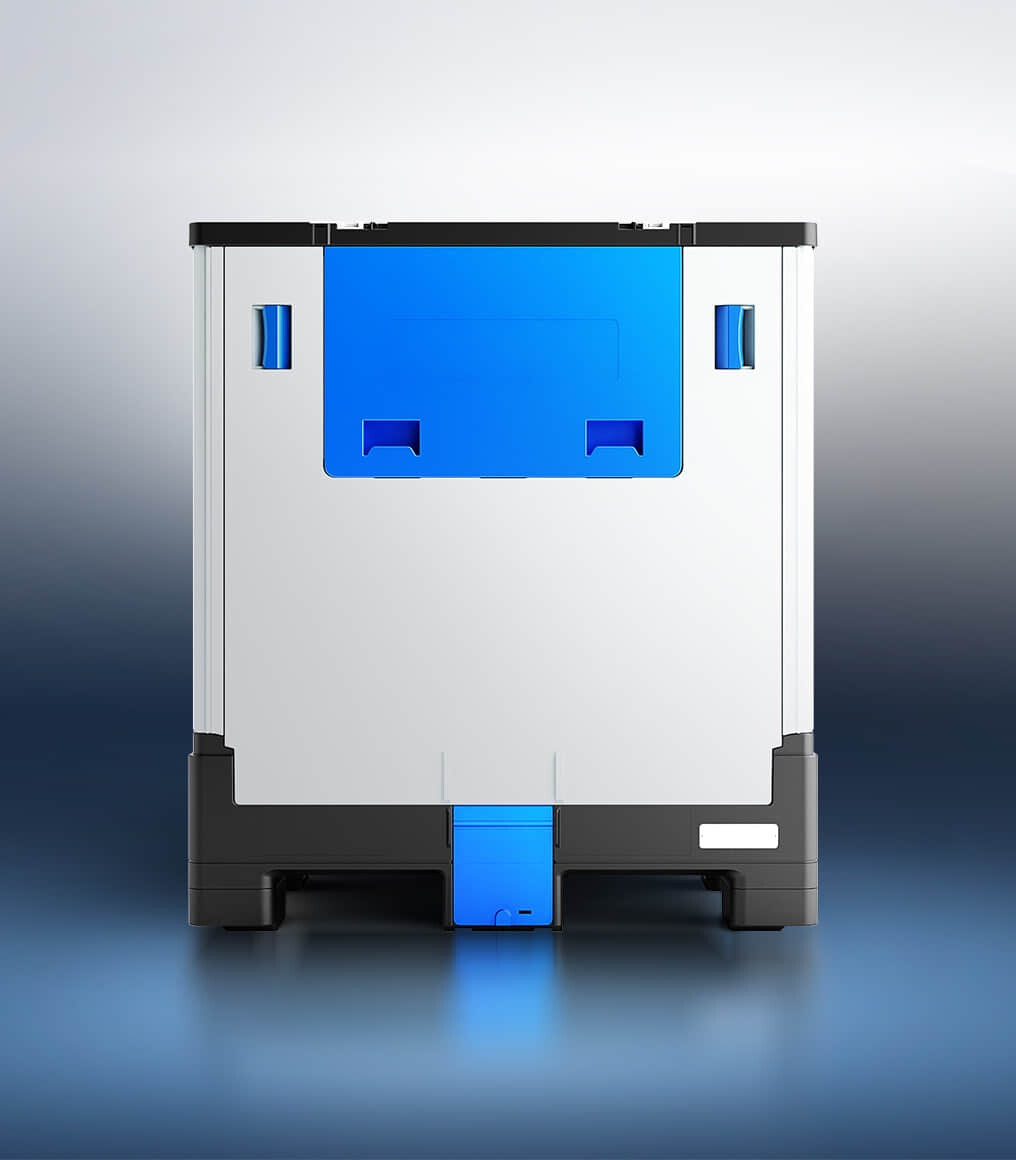

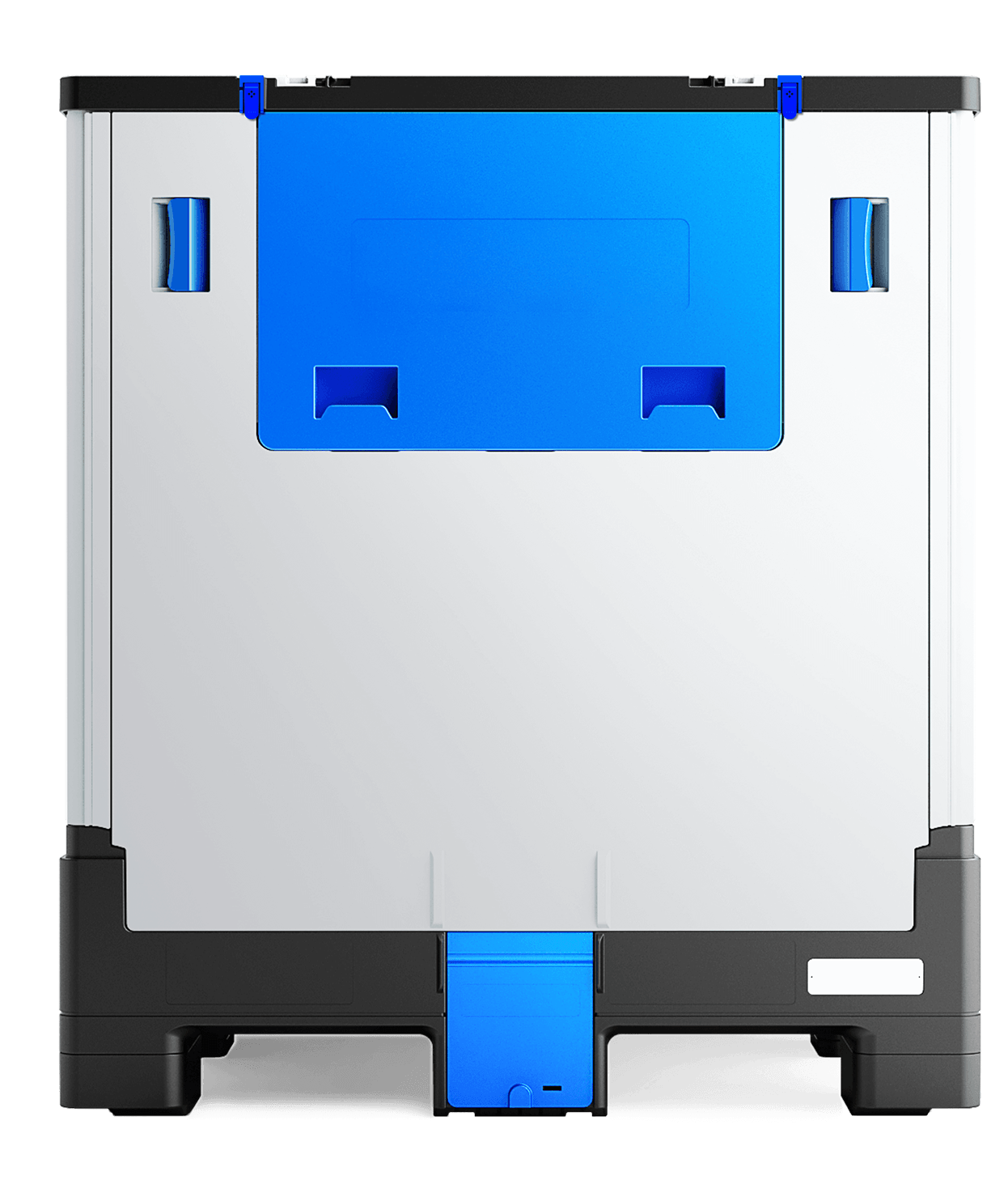

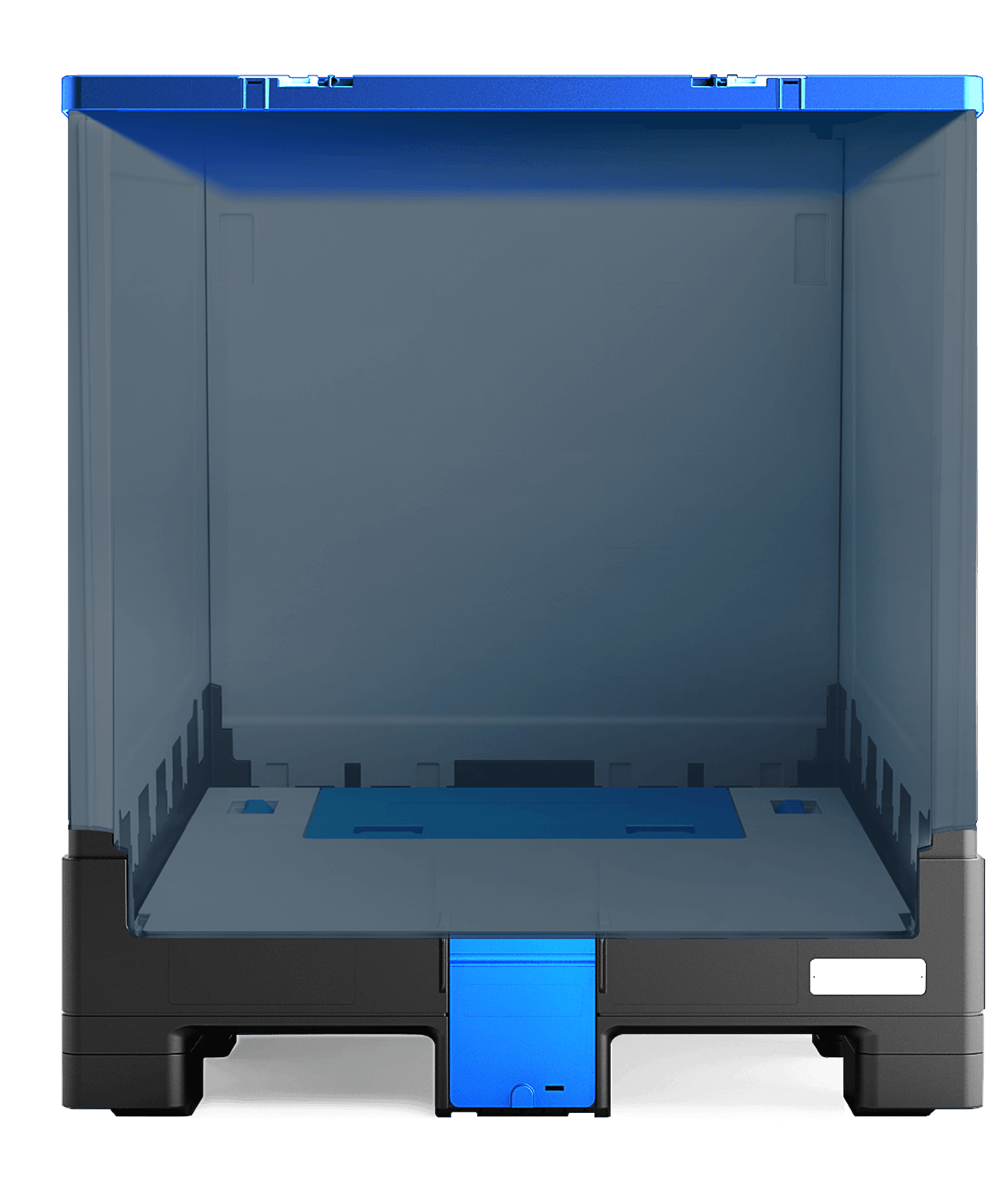

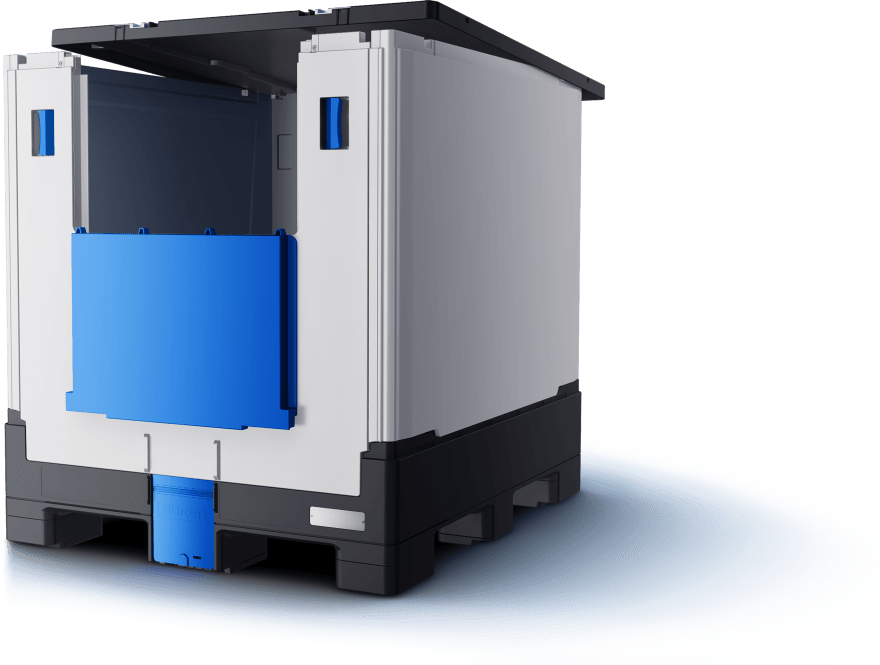

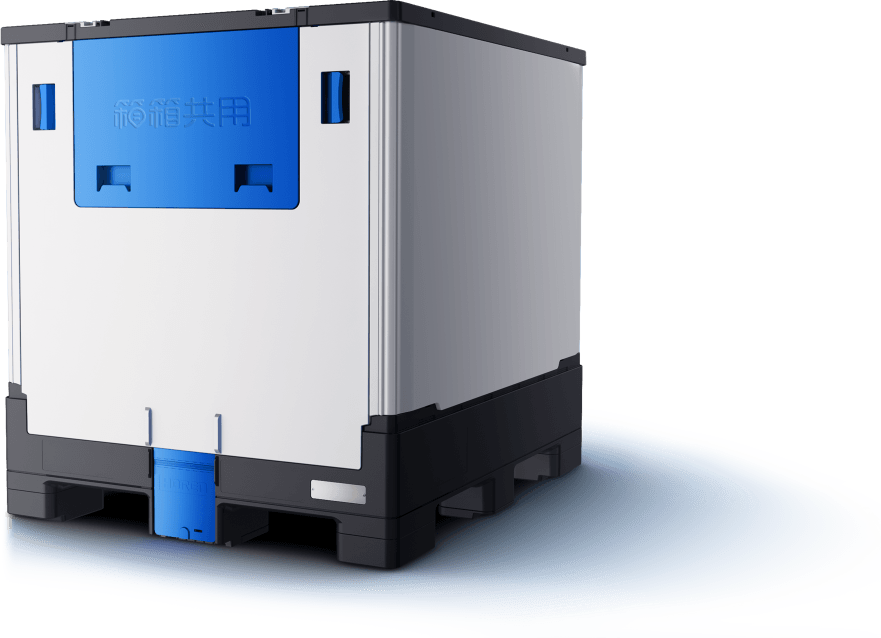

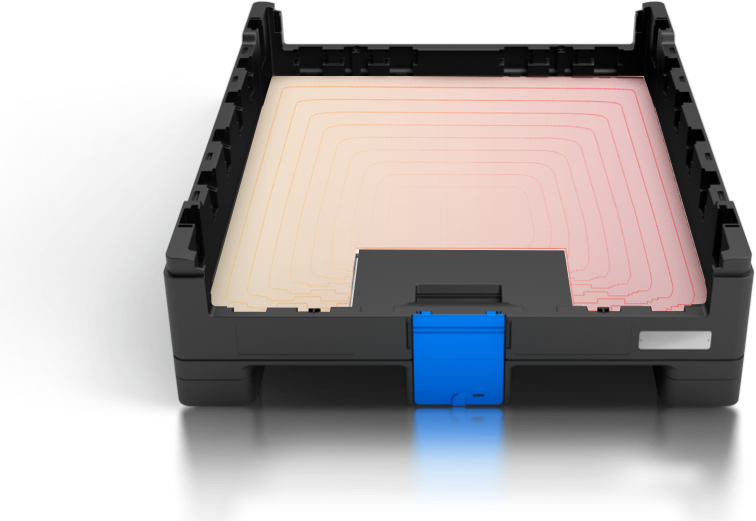

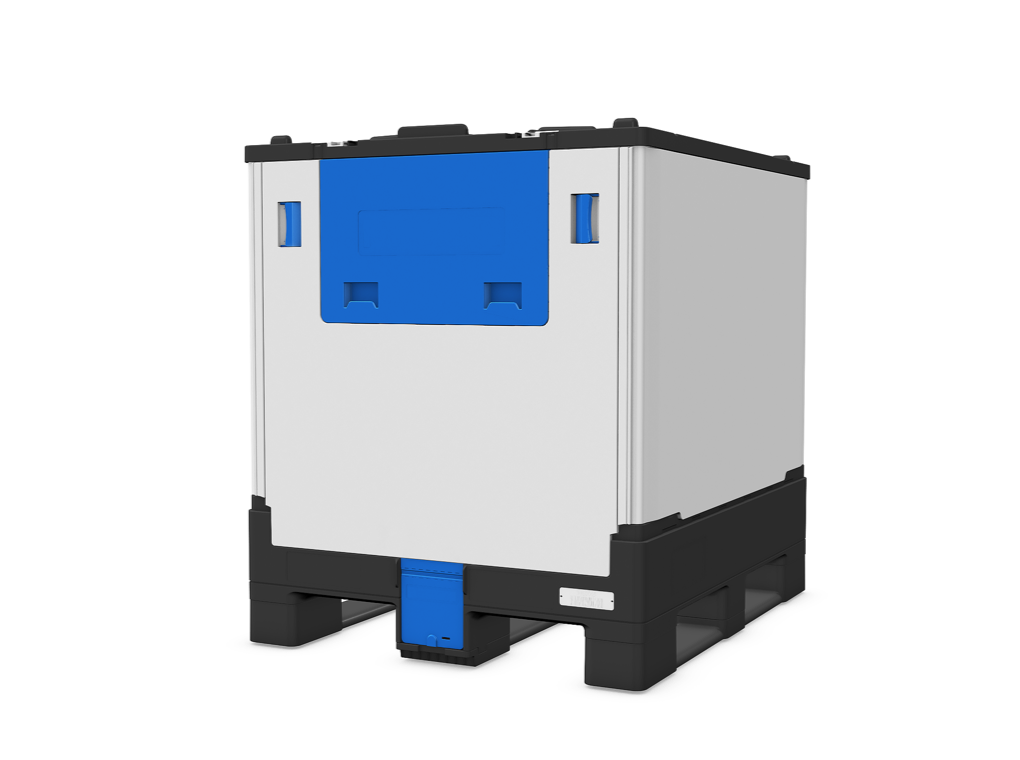

Double Smooth SurfacesA Balance between Aesthetics & Functionality.With an innovative double internal-external smooth surface design, the side panels and base of each IF1040 are reinforced with steel tubes, not only making the containers much more robust, but also offering easy cleaning.