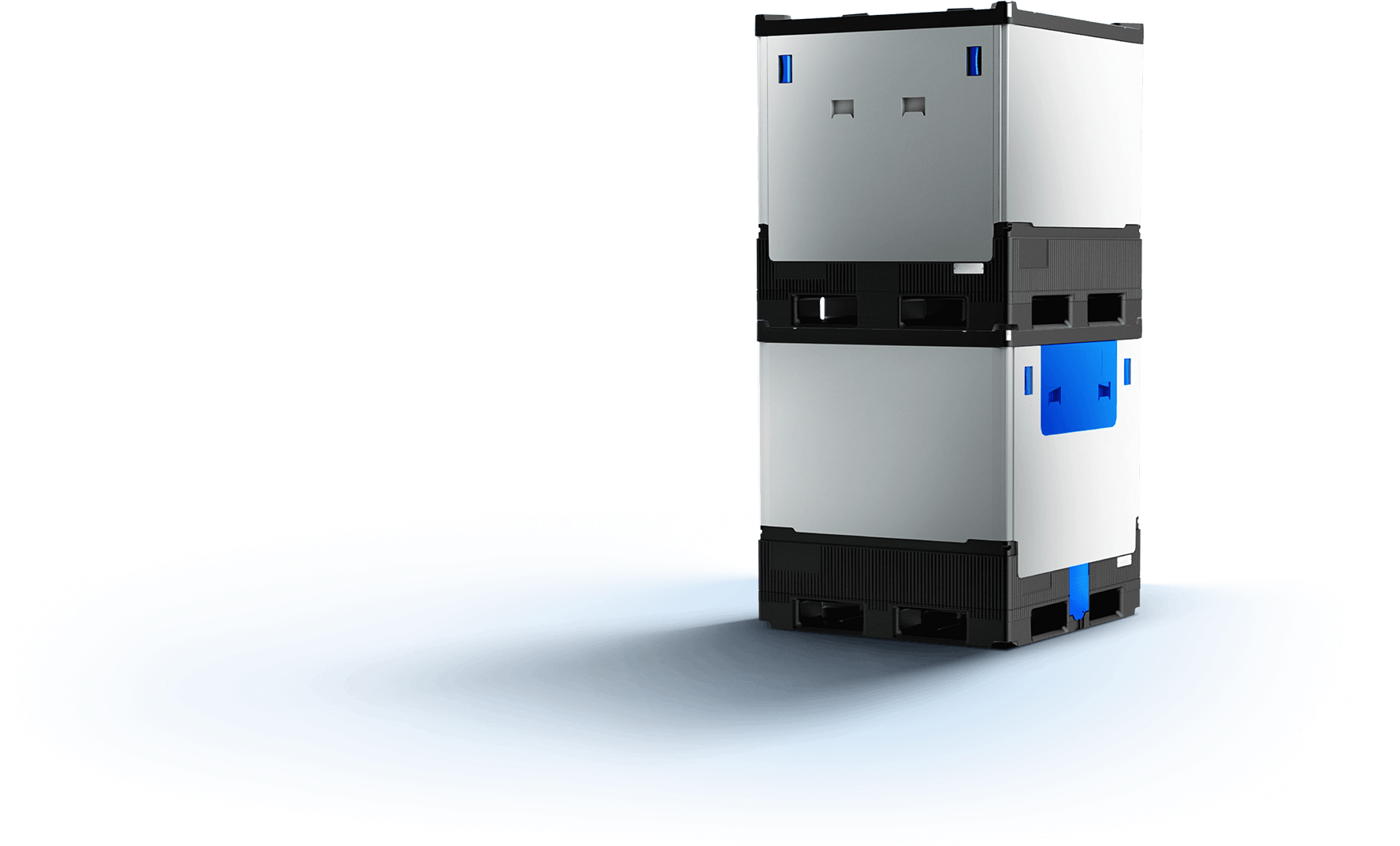

T11Benefits at a glance.

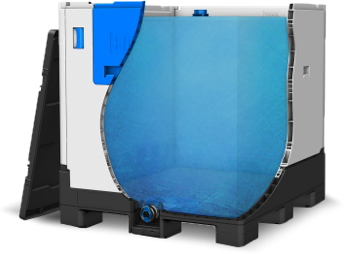

IBC T11 VS IBC Tank

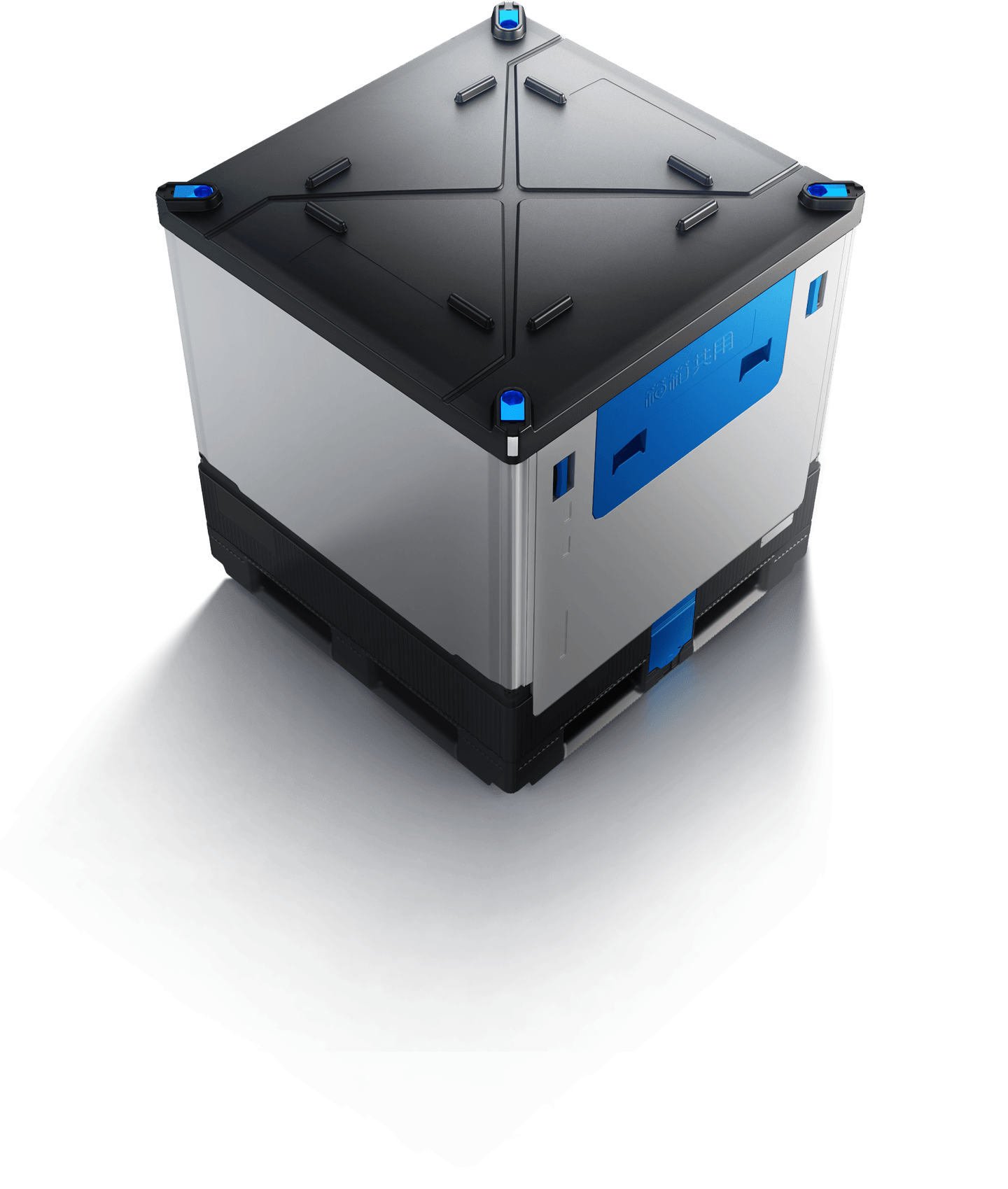

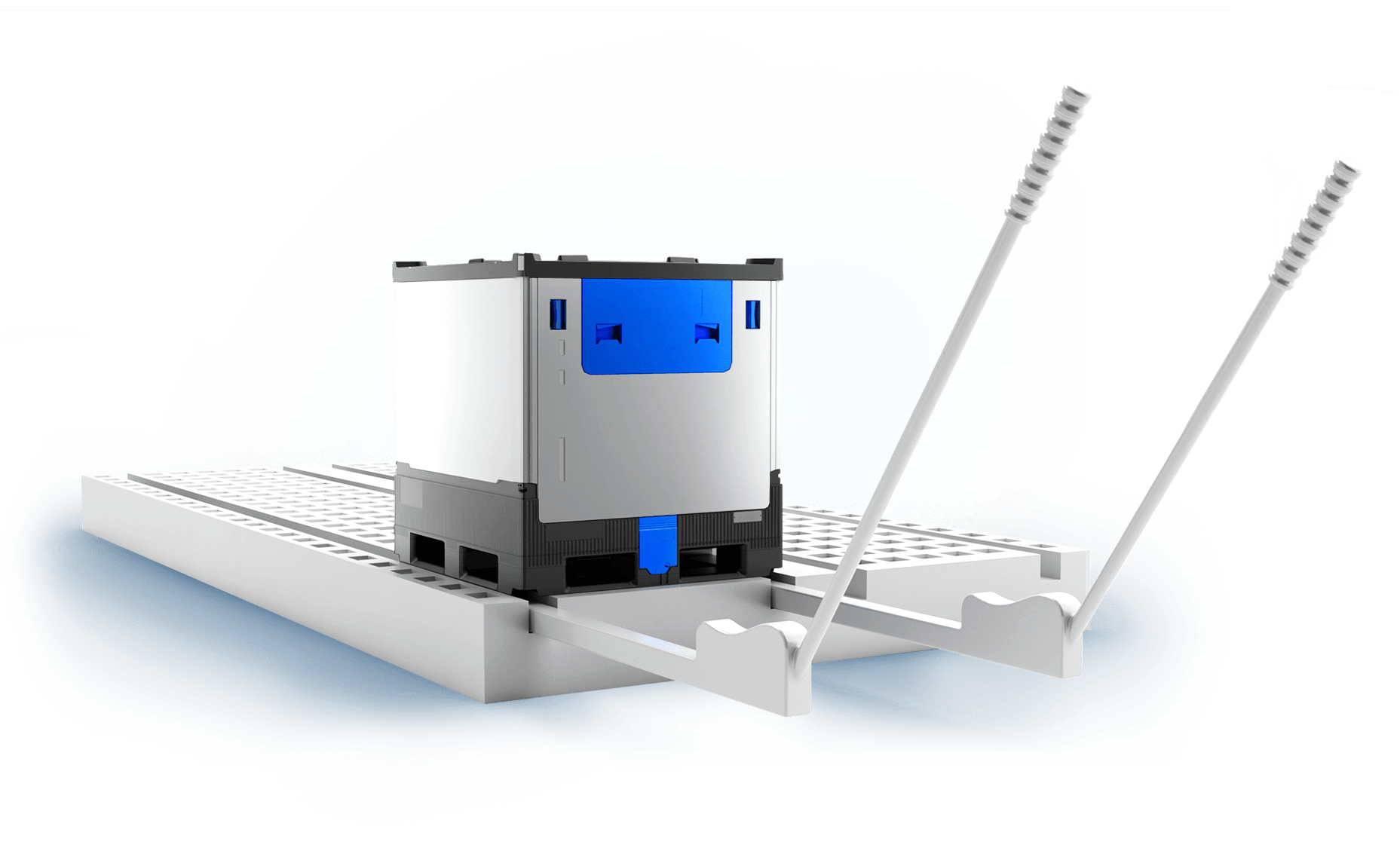

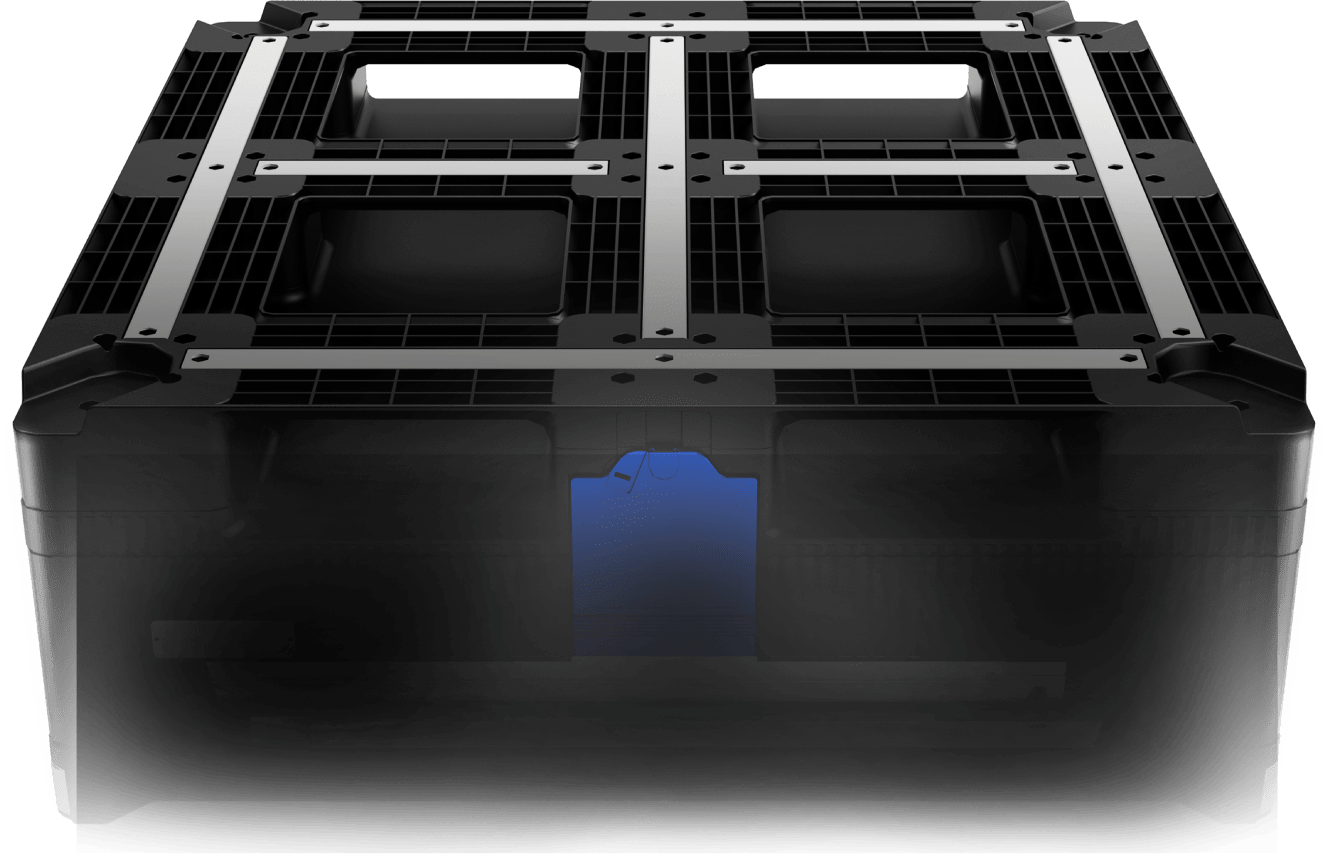

Reduced costs.The foldable containers save more than two-thirds of storage* and transportation space, effectively reducing return logistics costs.

Long service life. IBC T11 can be recycled and serve for up to 10 years, compared with the regular IBC tanks of 2-3 years’ service life. Easy cleaning. In contrast to regular IBC tanks, with a high cleaning cost, IBC T11 is easy to clean, and does not produce large amounts of waste water.

Easy cleaning. In contrast to regular IBC tanks, with a high cleaning cost, IBC T11 is easy to clean, and does not produce large amounts of waste water.

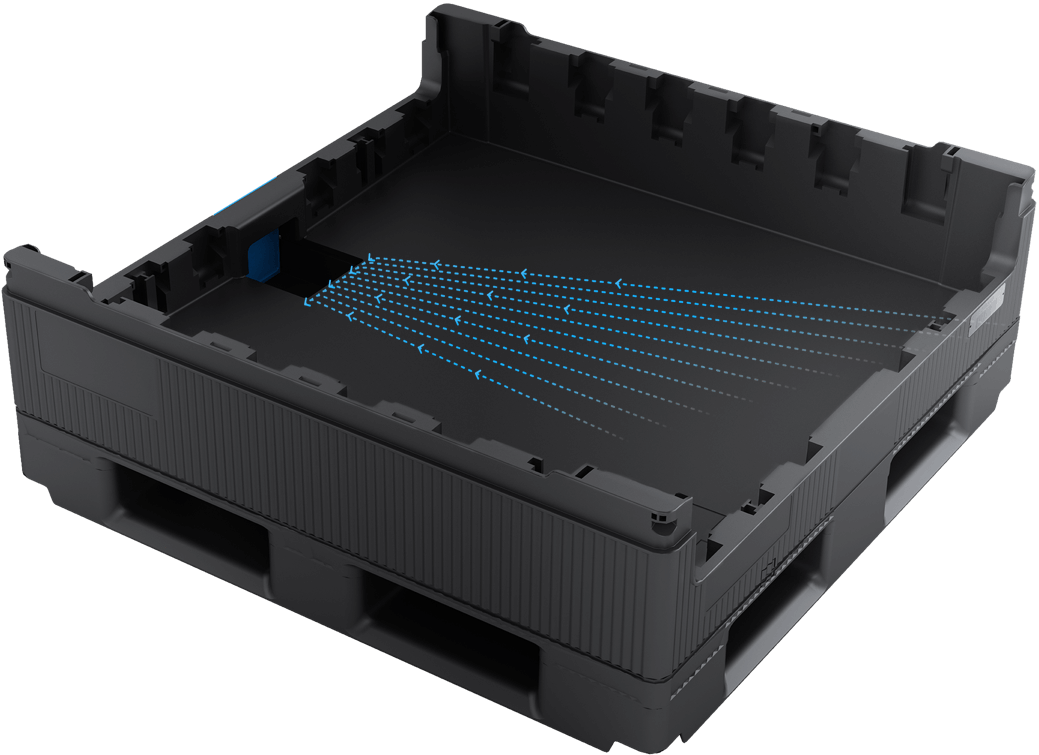

Lower crusting risks. The liner can be compressed to create a vacuum space during discharge, and partial discharge can also prolong their shelf life.

Reduced discharge residue. More thorough discharge ensures reduced liquid residue in the liner.

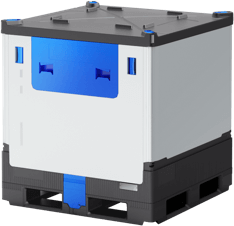

IBC T11 VS Wooden Container

Reduced costs.IBC T11 can be recycled and serve for up to 10 years, saving costs for users and also producing less packaging waste.Manual operation. IBC T11 features a stable structure, and it is easy to fold and unfold, saving manual labor in operation.

Manual operation. IBC T11 features a stable structure, and it is easy to fold and unfold, saving manual labor in operation.

Easy cleaning. The exclusive smooth double surface design ensures hygiene and easy cleaning, which leads to lower possibility of dust pollution, bacterial contamination, or insect attack.

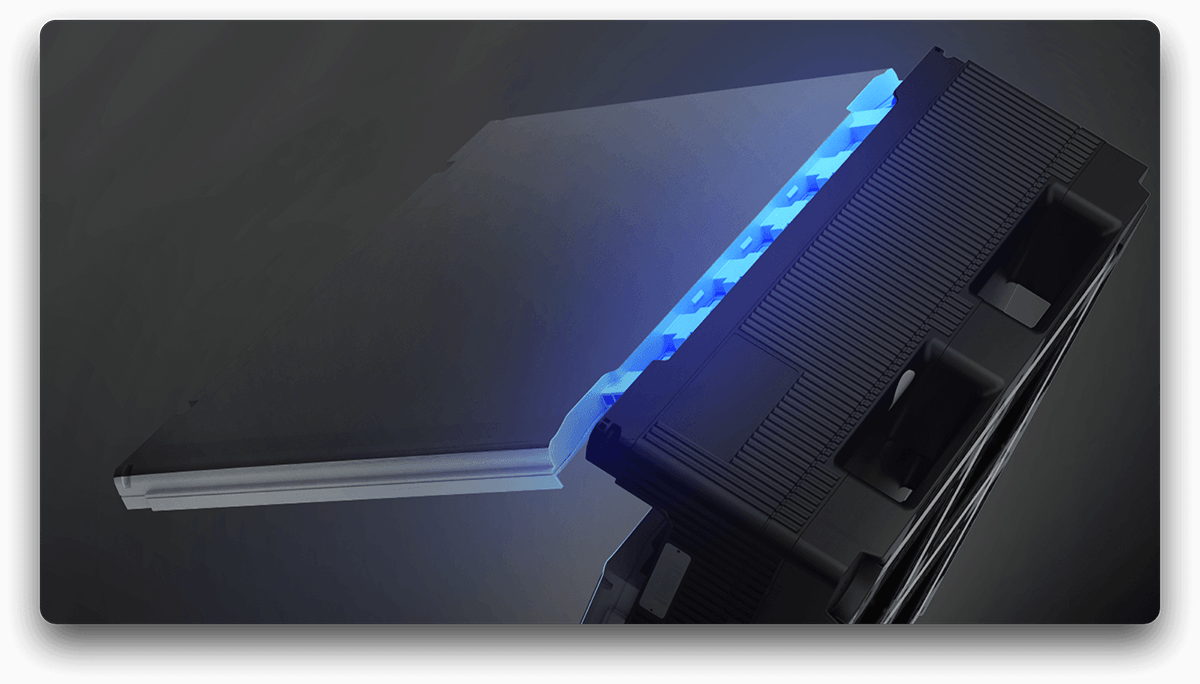

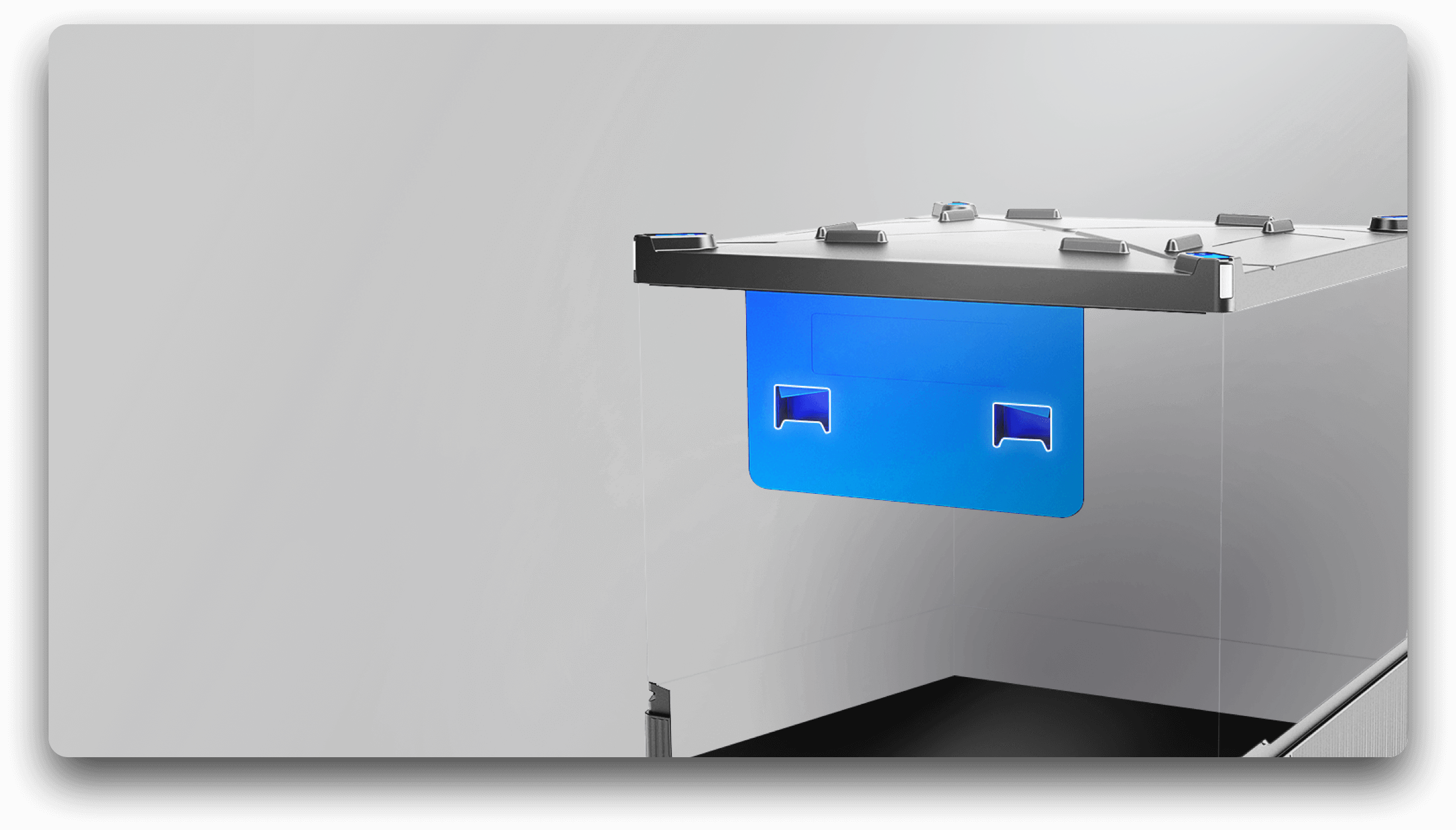

Easy usage.The innovative drop door on the short front panel makes liner installation easier.

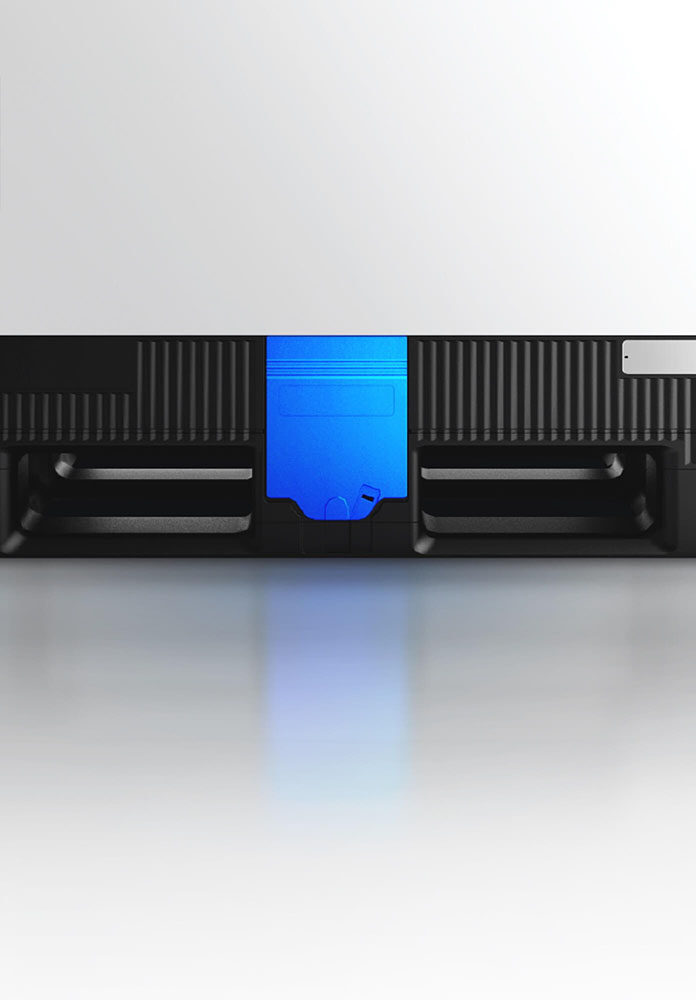

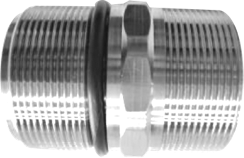

Low operational risk. The IBC T11 is both filled and discharged at the container bottom, reducing the risk of misoperation, and the sump is equipped with a stable valve or flange.

IBC T11 VS Metal Barrel

Large capacity. Each IBC T11 is equivalent in capacity to 4-5 metal barrels, which effectively saves time for manual operation.

Convenient manual operation. IBC T11 is fitted with a stable base for high handling efficiency.

Reduced footprint space.IBC T11's cubic construction maximizes space use in any transportation and storage tool, while round metal barrels tend to waste a lot of space.

Reuse. In contrast to disposable metal barrels, IBC T11 can be reused for about 10 years.

High security. IBC T11 protects products in a stable manner, with high safety and reliability factors.

IBC T11 VS Paper Container

Reduced costs. IBC T11 can be reused and serve for up to around 10 years, saving costs for users and also producing less packaging waste.

Manual operation. IBC T11 features a stable structure, and its plasticity from plastic materials makes the container easy to fold and unfold, saving manual labor in operation.

Easy cleaning.The exclusive double smooth surface design ensures hygiene and easy cleaning, which reduces the possibility of dust pollution.

Easy use.The innovative drop door on the side panel is designed for easy liner installation.

Low operational risk.The sump is equipped with a stable valve or gland, reducing the risk of misoperation.

IBC T11 VS Metal IBC

Reduced costs. The double smooth surfaces produced using a special process effectively protect the liner without extra protective layers.

Lightweight and easy operation. IBC T11 is over 50% lighter than metal IBCs, making manual operation easy.

Easy cleaning.The smooth double surface design ensures hygiene and easy cleaning, which leads to lower possibility of rust or pollution.

Low maintenance costs. Metal IBCs are susceptibility to de-soldering and other defects, while IBC T11 is made from plastic and foldable, which means lower maintenance and repair costs.

Easy installation.The plastic foldable IBC T11 features an innovative drop door for easy liner installation, coupled with a more user-friendly sump + valve combination.