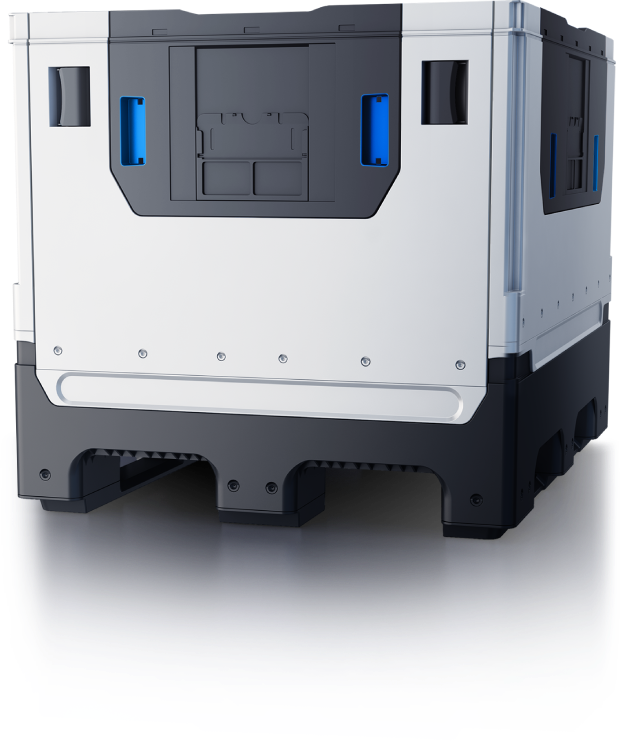

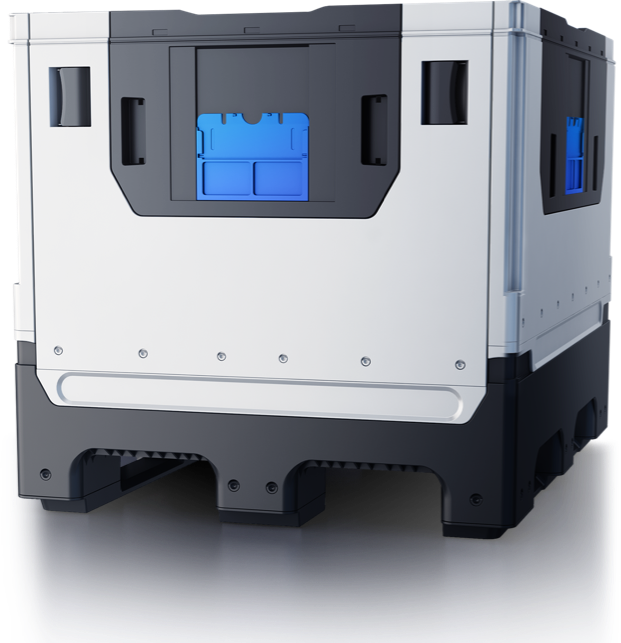

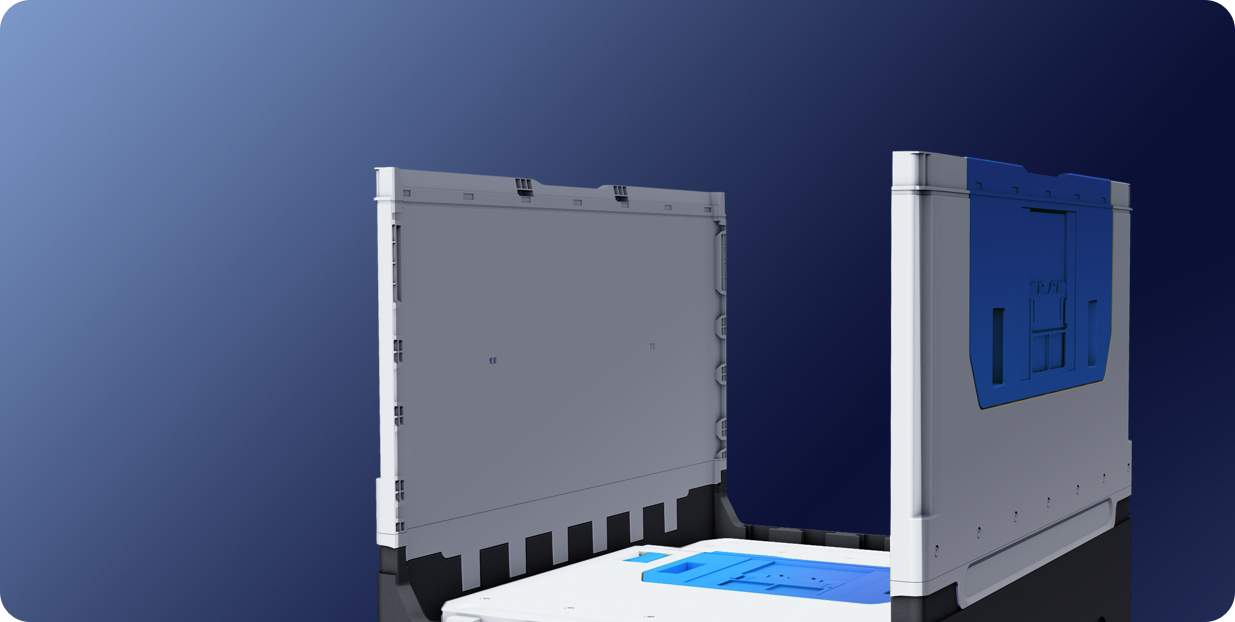

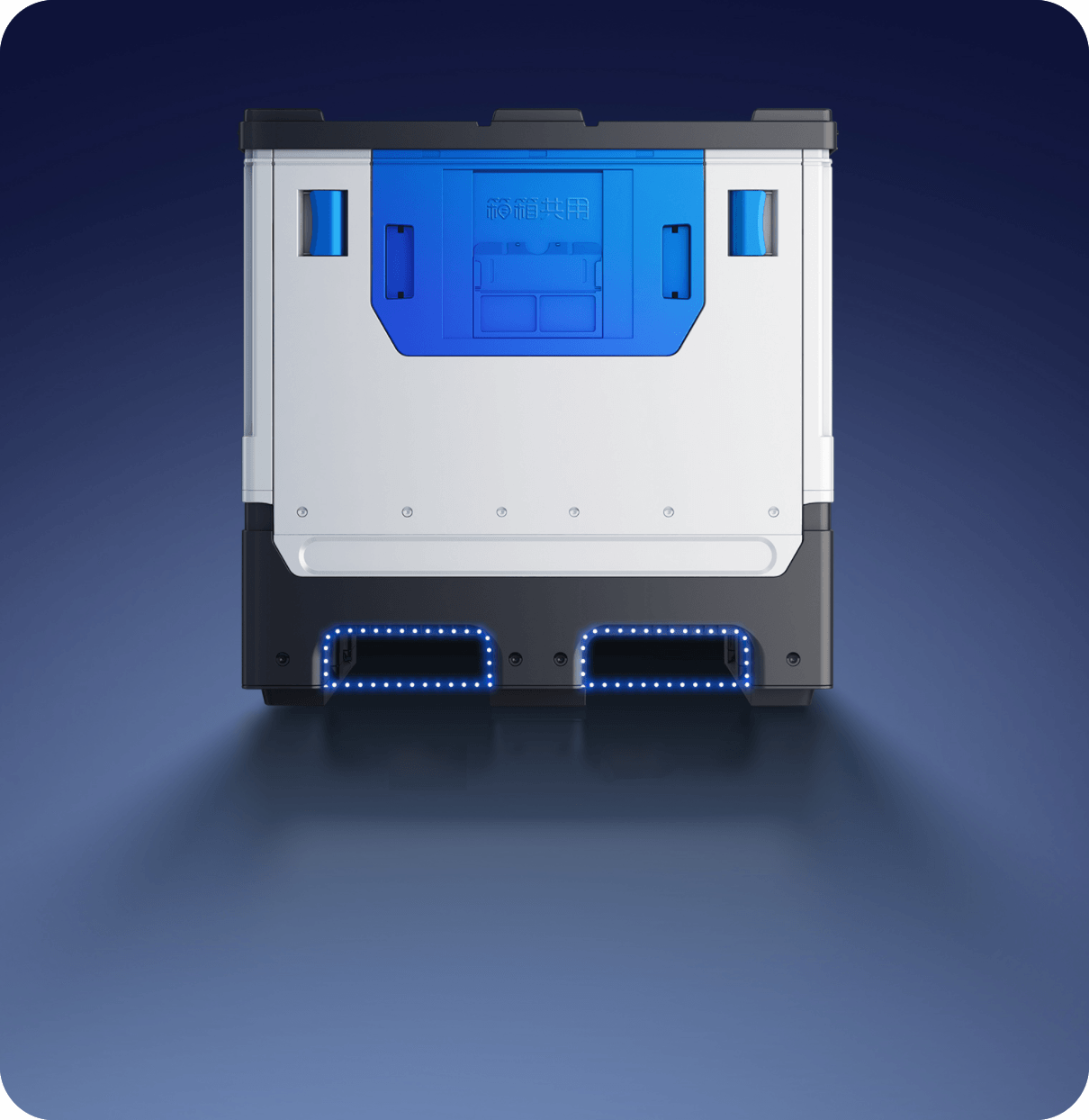

User-friendly design.

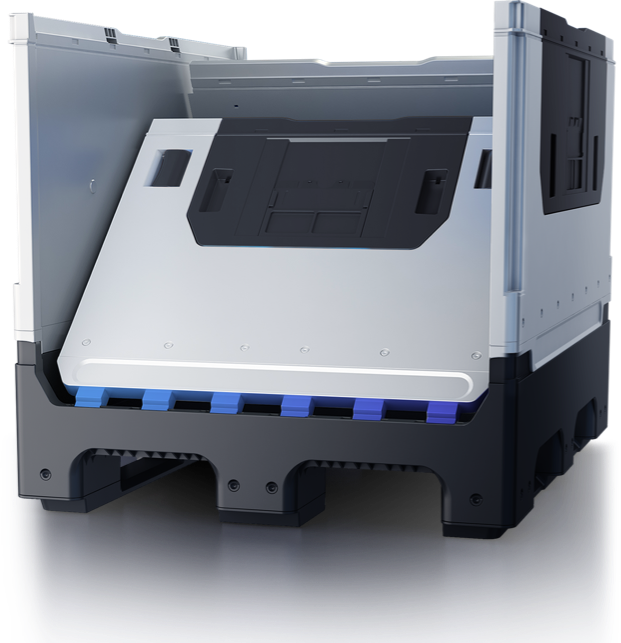

Classic lock, easy to operate. It allows operators to unlock side panels easily,

and when erected, the panels are automatically locked. The enlarged locking space makes operation easy

even when wearing gloves.

and when erected, the panels are automatically locked. The enlarged locking space makes operation easy

even when wearing gloves.

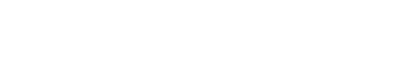

Card holders for rapid Identification. All four side panels are equipped with A5 card holders, makin tion during the transport of a large quantity of goods. Colored cards can also be used to make identification even quicker.

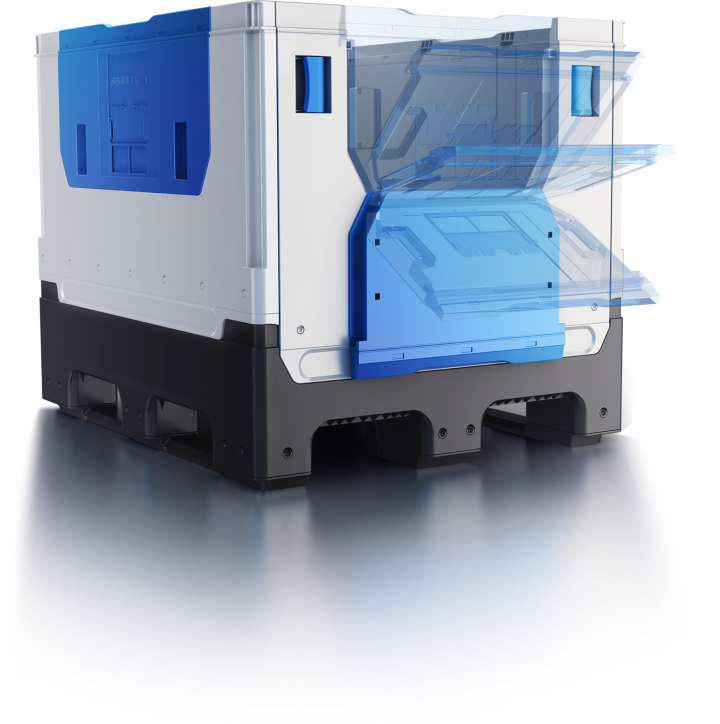

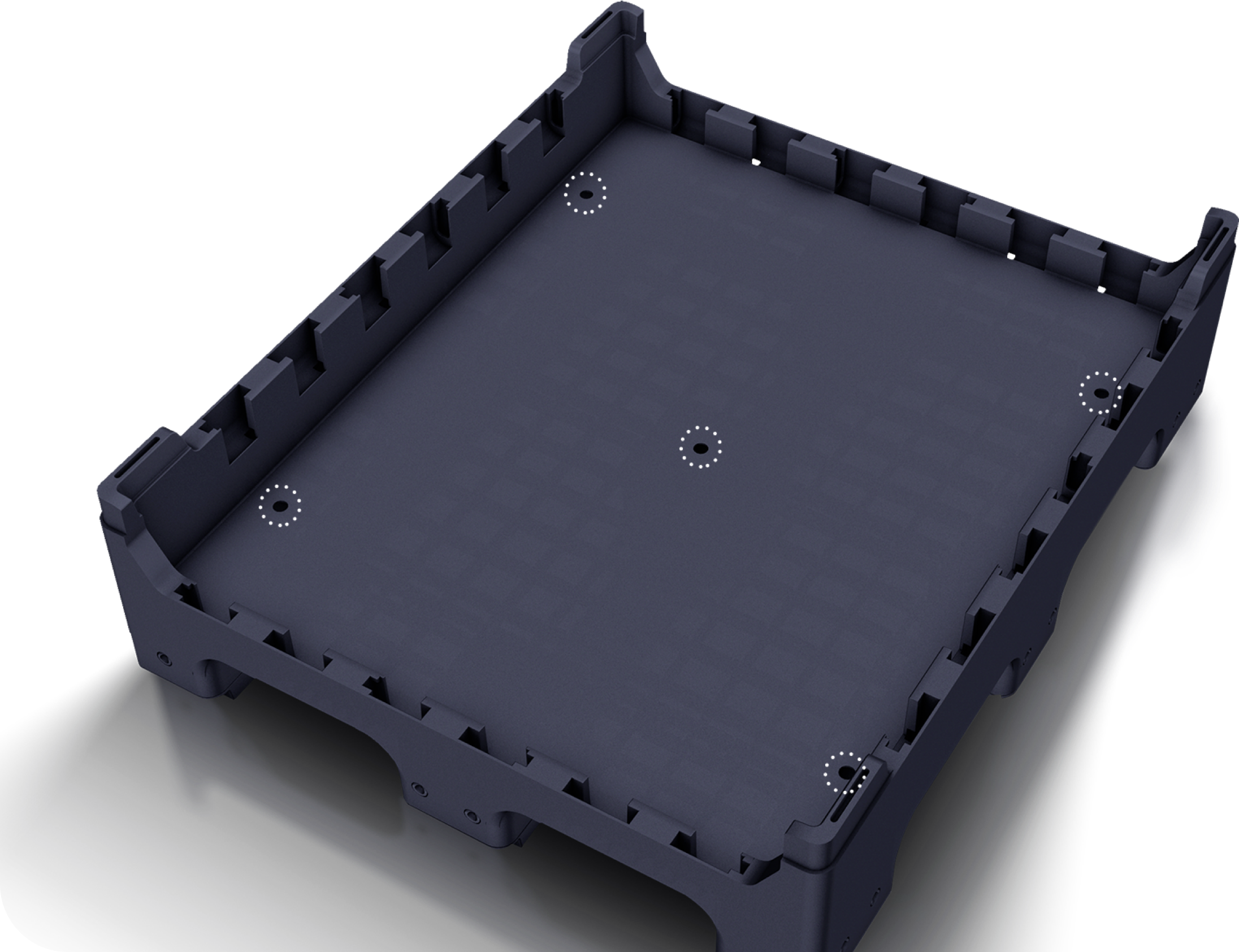

Hidden hinge. Side panels are connected to drop doors and the base with hidden hinges to avoid the build-up of dust - resulting in cleaner, tidier containers. The drop door is also simpler to open and close.