LWFLC

VideoBrochuresSpecifications

Inquiry

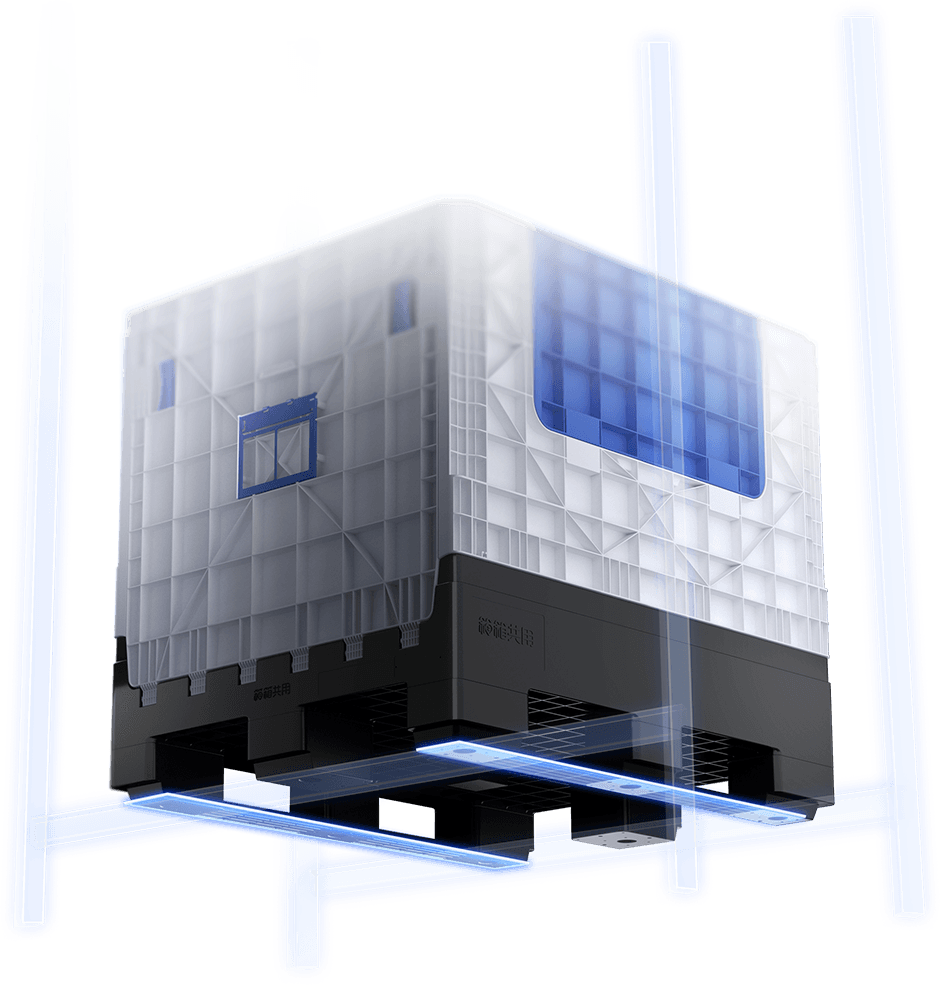

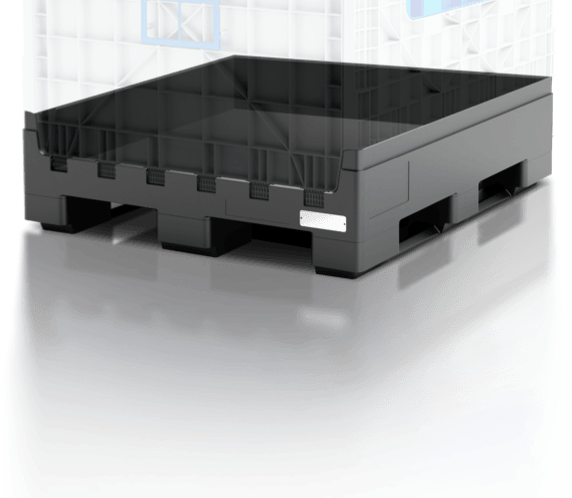

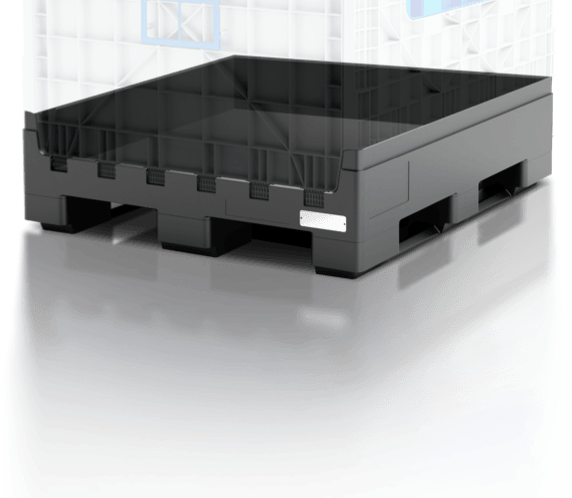

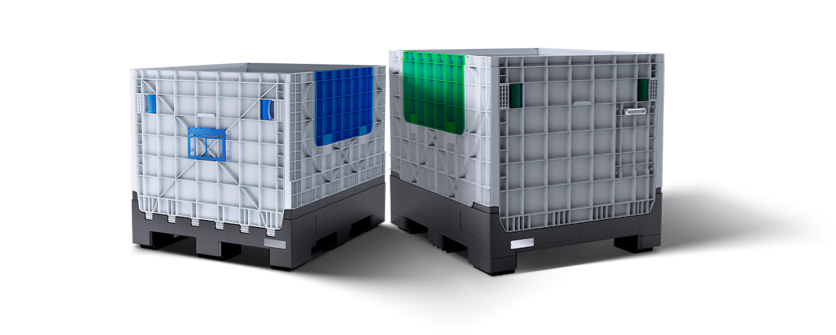

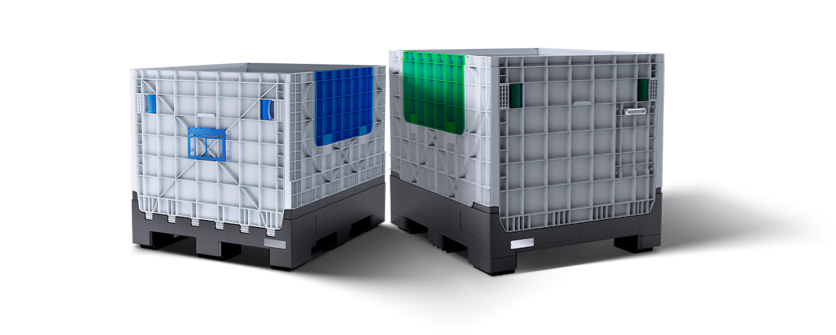

Super lightweight, more space.HOREN has made breakthroughs in minimizing the weight of containers with full respect to international standards. Its American standard LWFLC weighs only 31.7kg and can be operated by one person; the Asia-Europe standard LWFLC weighs 37.8kg.

400kgUnit Load.

2000kgStatic load 1+3.

1000kgDynamic load 1+1.

2 skids baseAdapted to racks

highly efficient.With 2 side skids allow the container to be adapted to racks. Fast and easy folding and erecting means the return efficiency is greatly improved, making it superior to conventional sleeve packs.

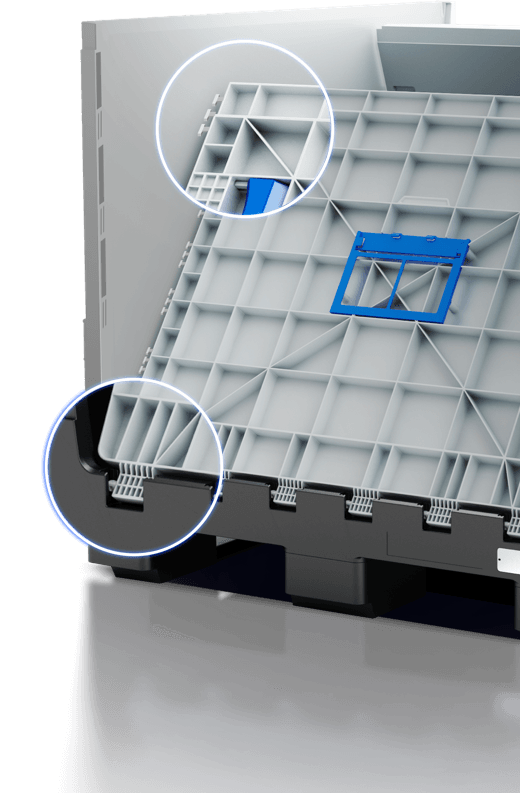

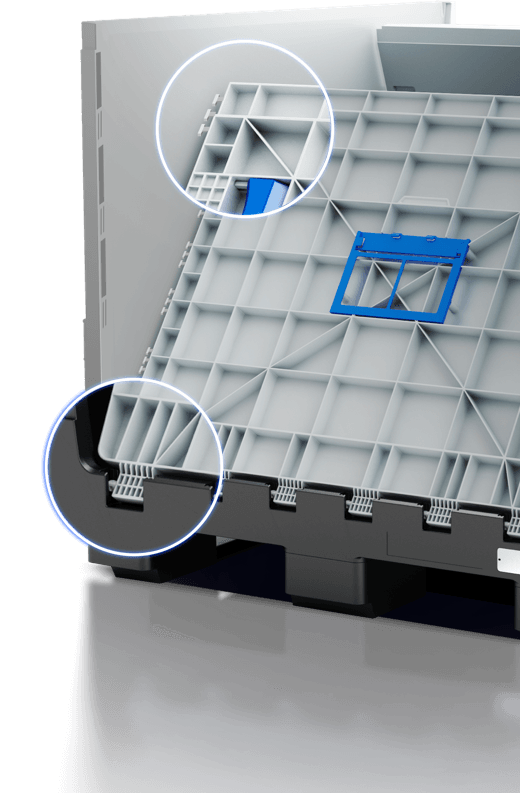

Label holderRapid identification.Asia-Europe standard LWFLC are equipped with label holders for product information. Different colors and design labels allow rapid identification, making LWFLC especially suited to the postal and parcel industry.

Plastic Anti-loosening Bolts. For Asia-Europe standard LWFLC, the base and feet are connected by plastic anti-loosening bolts, which are more reliable and more efficient in disassembly and assembly than traditional metal screws.

User-friendly design for smart logistics.

Strengthened occlusion.The combination of T-shaped structure and dovetail structure leads to greatly strengthened occlusion.

Non-sequential folding.The unique robust hinge between side panels and the base allows easy installation without tools, as well as non-sequential folding.

Protection details.The anti-dumping design on long side panels protects operators from injury; and the round-edge fork holes make forklift operation easy and safe.

Reinforced base.The Lightweight FLC’s inclined arc-shaped skid and top edge make it fit with most folding containers on the market. The reinforced base ensures high stability and impact resistance.

Bespoke colors at your option.

High reliabilityInternationally authoritative

certifications, robust beyond

imagination.Lightweight FLC has passed the general simulation performance test for packaging (ISTA-3E) and the D4169 - 08 Performance Testing of Shipping Containers and Systems by the International Safe Transit Association (ISTA) and the American Society for Testing and Materials (ASTM) respectively. LWFLC’s high quality and reliability are well-proven.

Horizontal impact test.Full load, two-layer stacking, set a backstop, about 8 inches from the top of the lower box, start from the final velocity of 2mph (0.89m/s); if there is no abnormality, increase by 0.5mph ( 0.22m/s) each time.

Crush test.No load, place the container in the center of the pressure equipment, the upper pressure plate pressurizes at a speed of 0.5”/min (12.7mm/min) until the sample is crushed.

Foot impact.Restrict the horizontal movement of the container, impact 2 side feet and 1 middle foot with a fork-shaped pendulum bob device; for each time the sample passes the test, the height is increased by 2 inches.

Dynamic deflection test.Full load, two-container stacking, under random vibration mode applied by ISTA 3H, set Grms=0.54, perform 180-minute random vibration at 1-200Hz, and measure the deformation of the bottom of the upper box.

Static deflection test.Full load, two-container stacking for no less than 3 consecutive days, measure the deformation of the bottom of the upper box.

LWFLC

Lightweight

Both America and Europe standard available

Compatible with racks

Non-sequential folding

Label holders

Bespoke colors

CHECK THE TECHNIAL DATA

Inquiry

All the data on this website is provided by HOREN unless otherwise stated.

*Full load: Only when the liquid density ≤ 1.35g/cm³.

*High reliability test: All tests are tested at HOREN’s standard labs in simulation of the conditions required by ISTA and ASTM.

*Traditional non-foldable IBC: Non-foldable plastic IBC tanks in general on the market with dimensions of 1200x1000x1145mm.

*Regular plastic foldable IBC: IBCs on the market under Asian and European standards and with dimensions of 1200x1000x1140mm and volume of around 1000L. Thus IBC OF330, with a volume of 1249L, is about 25% larger.

*Two-thirds: The volume of a folded IBC is approximately 1/3 of that when unfolded. So compared with a non-foldable container of the same size, 2/3 of the storage space is saved for return transport.

*Three-quarters: The volume of a folded IBC OF330 is approximately 1/4 of that when unfolded. So compared with a non-foldable container of the same size, 3/4 of the storage space is saved for return transport.

*Service life of up to 10 years: Measured in accordance with the limited conditions in HOREN’s standard labs.

*TE pin: Available upon request and purchase.

*Heater pad: Available upon request and purchase.

*7.6:1: The ratio of the volume of an erected KingKong RPC to that when folded is approximately 7.6:1.

*31%: Obtained upon measurement of multiple products under the same conditions of compression test in HOREN’s standard labs.

*No Crate Change: Goods stored in HOREN’s crates can be directly transported from farm or place of origin to market for display and sale, without the need to change to new crates.

*0.1%: In HOREN’s standard lab environment, 1000kg of 300,000-cP viscous liquid, after being discharging, leaves residues weighing <1kg.

*Hands-free: After RRS and liner are installed, no more manual operation is needed during the discharge process.

*Folding ratio 3:1: The ratio of the volume of an erected FLC KF975 to that when folded is approximately 3:1.