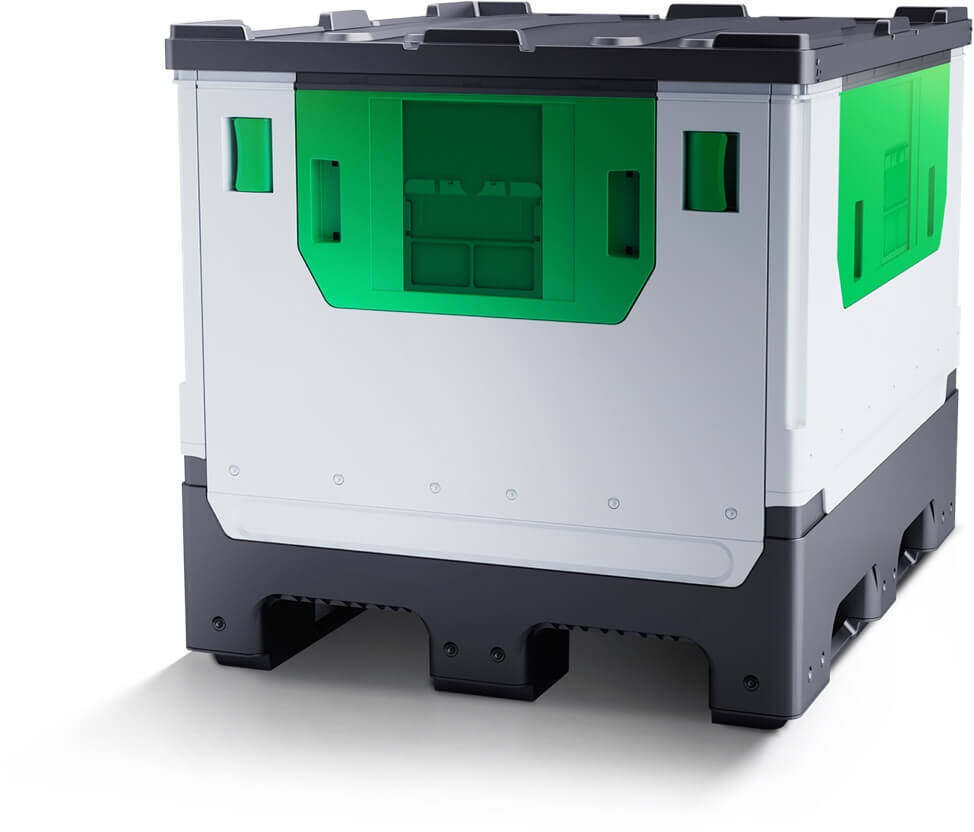

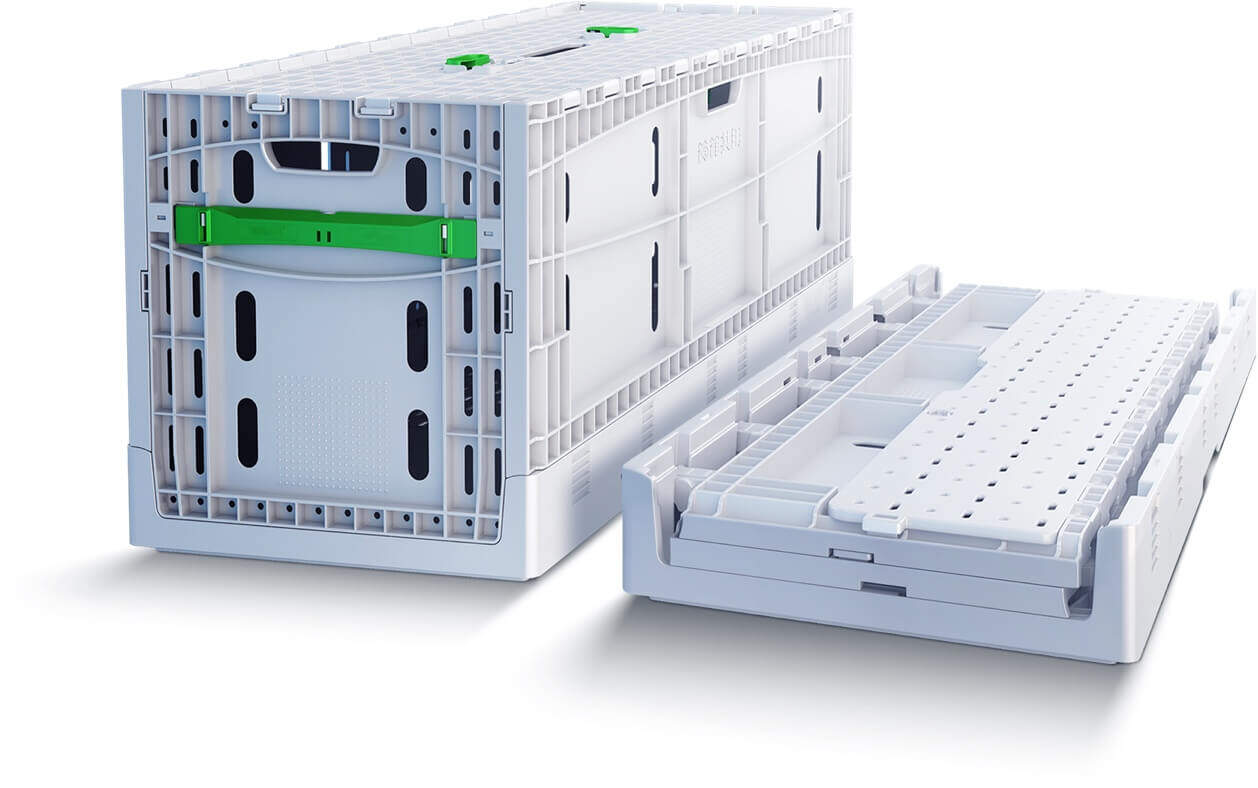

RPCFoldable reusable crates

with diverse models.

with diverse models.

RDU250Kg loading capacity,

from farm to supermarket.

from farm to supermarket.

KF975840L loading volume,

double smooth surfaces.

double smooth surfaces.

Flower CrateSix-way ventilation,

born for freshness.

born for freshness.

Full-range load capacity solutions

for fruits & vegetables.5kg~600kg

for fruits & vegetables.5kg~600kg

Max unit load.5kg~30kgApplication to most kinds of vegetables, fruits, meats, non-staple foods,

condiments, etc . support cross stacking and transport by pallet.

condiments, etc . support cross stacking and transport by pallet.

Max unit load.250kgApplication to melons and other hard-skinned fruits and vegetables such as watermelons, honeydews, potatoes, sweet potatoes, grapefruits, etc. useful in an array of scenarios including market displays, fast transport, and combined stacking.

Max unit load.600kgApplication to the transportation and storage of large fruits and vegetables such as pumpkins, wax gourds, durians, coconuts, jackfruits, etc.; capacity up to 600kg.

Advanced gas-assisted

injection molding process.Leading a clean and energy-saving future.

injection molding process.Leading a clean and energy-saving future.

no blind sngles.

reduced losses.

increased by 25%.

and microorganisms.

increased by 23%.

Thanks to the gas-assisted injection molding (GAIM) process, HOREN has managed to produce crates with thin walls and double smooth surfaces. This reduce the growth of bacteria or microorganisms, and allows quick cleaning and drying, thus lowering the costs. The thinner yet stronger structure avoids bumps and impacts and reduces damaged losses during transportation.

High folding ratio .Lower costs on return transportation.

High folding ratioWith its special structure, side panels can be rapidly folded and erected with high folding ratio, which has greatly reduced the cost savings for return and storage.

Unit-based transportStandard footprint design makes our RPC to be suitable for a wide range of pallets on the market, so that they can be stacked and transported by unit. It reduces damaged losses during transportation, ensuring safer and more efficient supply.

ONE TOUCHFrom farm to supermarket with lower loss.HOREN’s One Touch solution is a one-stop palletized packaging from the farm to supermarket directly without any unpacking and repacking. This perfectly protects fruits, vegetables and flowers from impacts and bumps during transport, keeping product loss rates below 5%. Since its launch in 2015, One Touch has become a standard configuration for the supply chains of many chain stores and supermarkets in China and abroad, especially popular among community-based chain stores of fruits, vegetables and fresh cut flowers, retail e-commerce etc. HOREN’s RPC has become an important technical skill to improve supply chain efficiency, reduce distribution and delivery losses, and improve product quality.

New symbol of green and circular economy.HOREN has successfully developed a series of reusable packaging solution that meets the complex demands for the preservation, cold chain, sorting, transportation, and storage of fruits, vegetables and fresh cut flowers. Relying on high folding ratio, moisture resistance, robustness, and high ventilation, our solution offers an alternative choice to replace disposable packaging, and reduces your supply chains’ impact on the environment.

ReducedSolid waste

ReducedGreenhouse gas

ReducedOzone layer

destruction

destruction

ReducedEutrophication

ReducedAcidification

ReducedSummer smog

CoRTP+AI+IP, New era of smart packaging.

Learn more

Our clients

All the data on this website is provided by HOREN unless otherwise stated.

*Full load: Only when the liquid density ≤ 1.35g/cm³.

*High reliability test: All tests are tested at HOREN’s standard labs in simulation of the conditions required by ISTA and ASTM.

*Traditional non-foldable IBC: Non-foldable plastic IBC tanks in general on the market with dimensions of 1200x1000x1145mm.

*Regular plastic foldable IBC: IBCs on the market under Asian and European standards and with dimensions of 1200x1000x1140mm and volume of around 1000L. Thus IBC OF330, with a volume of 1249L, is about 25% larger.

*Two-thirds: The volume of a folded IBC is approximately 1/3 of that when unfolded. So compared with a non-foldable container of the same size, 2/3 of the storage space is saved for return transport.

*Three-quarters: The volume of a folded IBC OF330 is approximately 1/4 of that when unfolded. So compared with a non-foldable container of the same size, 3/4 of the storage space is saved for return transport.

*Service life of up to 10 years: Measured in accordance with the limited conditions in HOREN’s standard labs.

*TE pin: Available upon request and purchase.

*Heater pad: Available upon request and purchase.

*7.6:1: The ratio of the volume of an erected KingKong RPC to that when folded is approximately 7.6:1.

*31%: Obtained upon measurement of multiple products under the same conditions of compression test in HOREN’s standard labs.

*No Crate Change: Goods stored in HOREN’s crates can be directly transported from farm or place of origin to market for display and sale, without the need to change to new crates.

*0.1%: In HOREN’s standard lab environment, 1000kg of 300,000-cP viscous liquid, after being discharging, leaves residues weighing <1kg.

*Hands-free: After RRS and liner are installed, no more manual operation is needed during the discharge process.

*Folding ratio 3:1: The ratio of the volume of an erected FLC KF975 to that when folded is approximately 3:1.