Pallet Collar

VideoBrochuresSpecifications

Inquiry

Space built from ground.

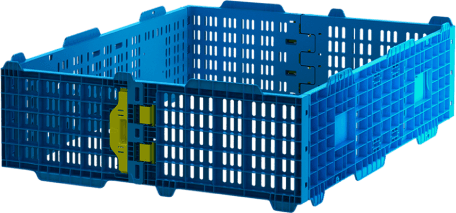

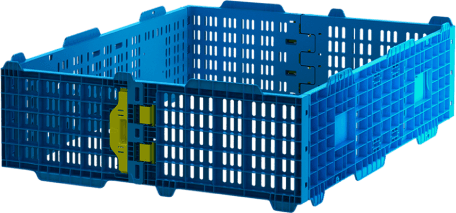

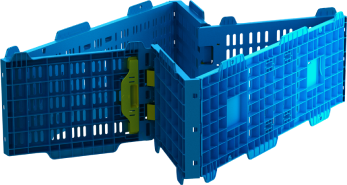

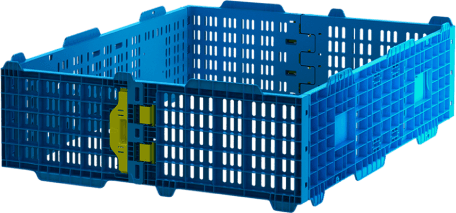

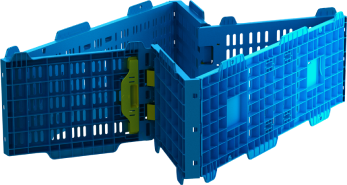

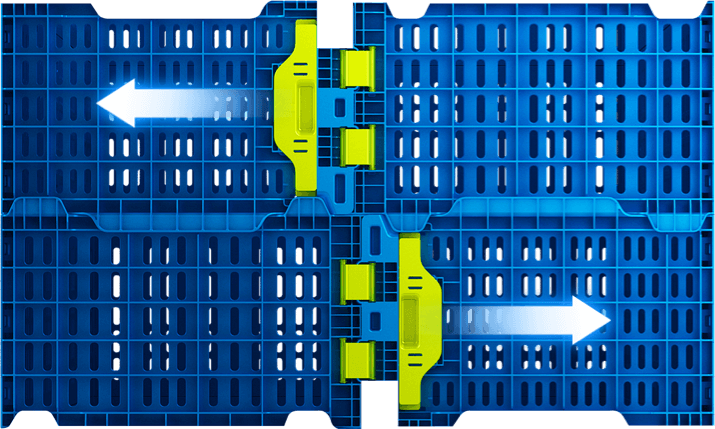

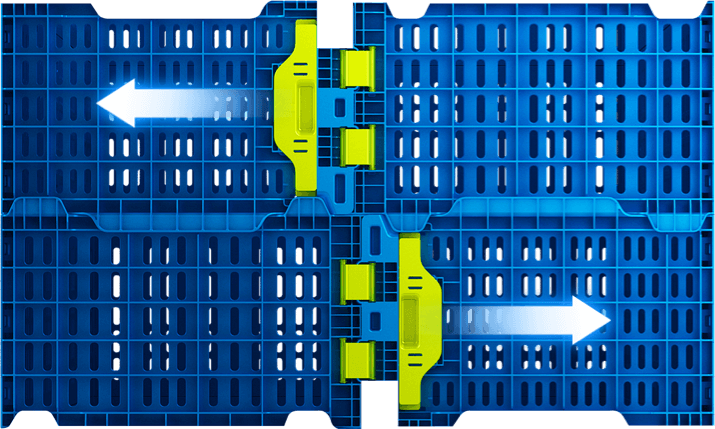

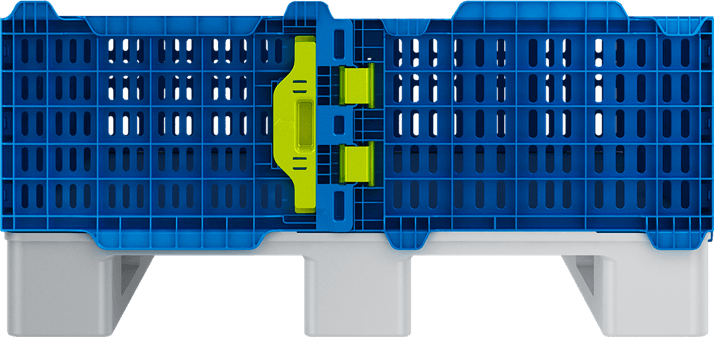

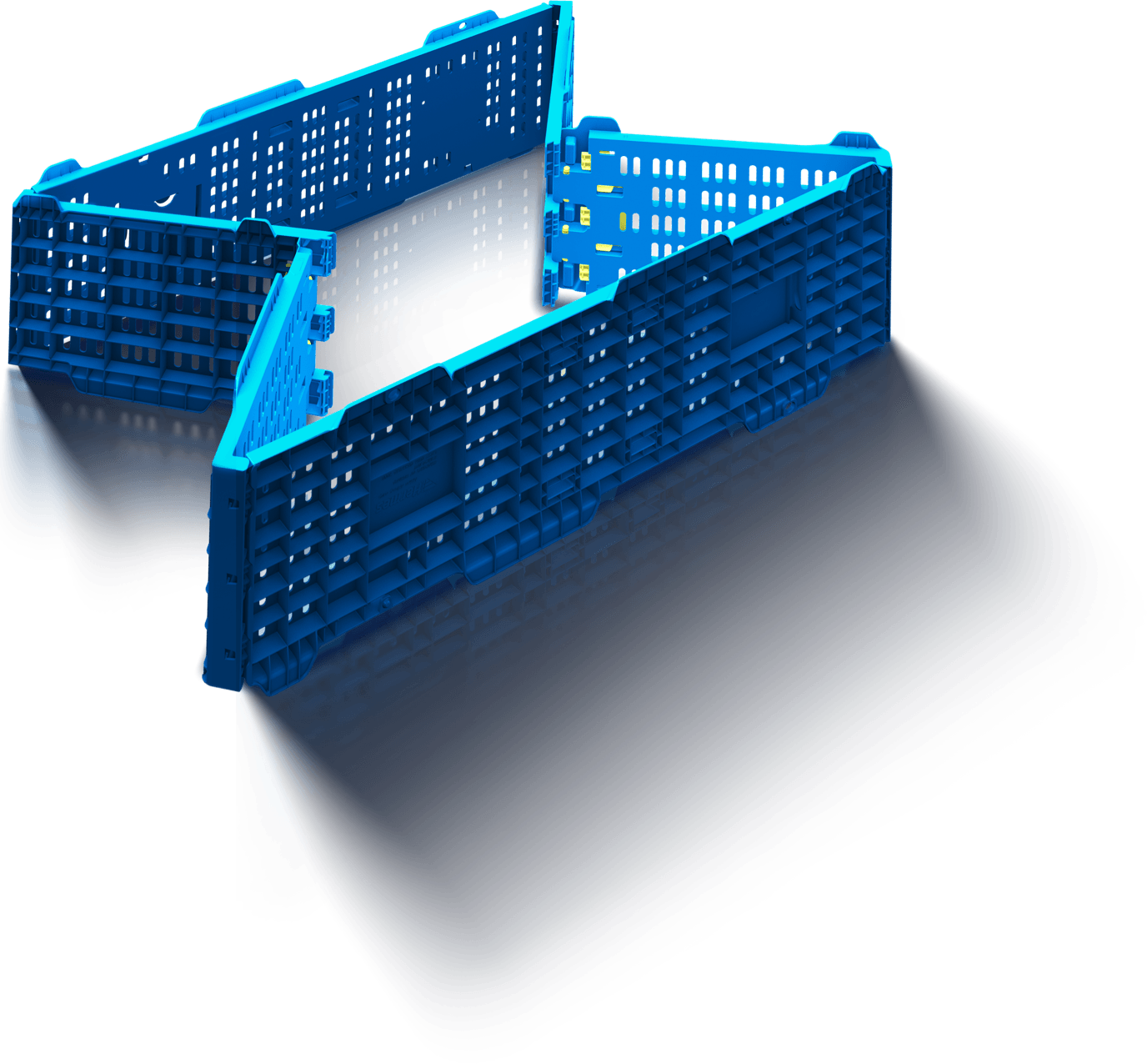

Pull and stretch to lock.The Pallet Collar’s innovative structure allows it to be unfolded smoothly. After being fully extended, it will automatically lock up.

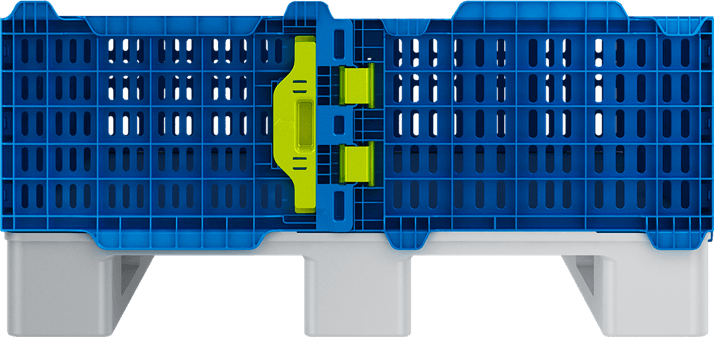

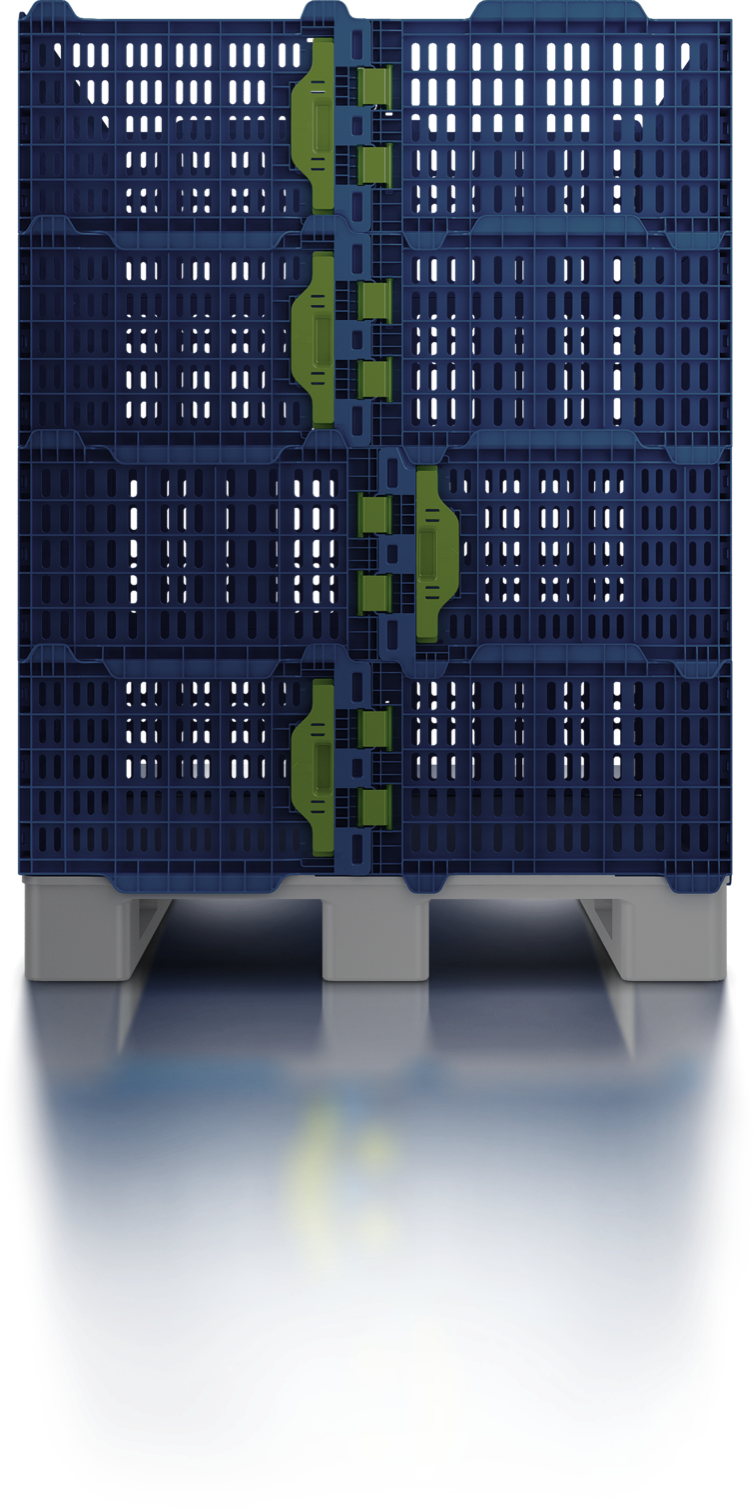

Flexible combination

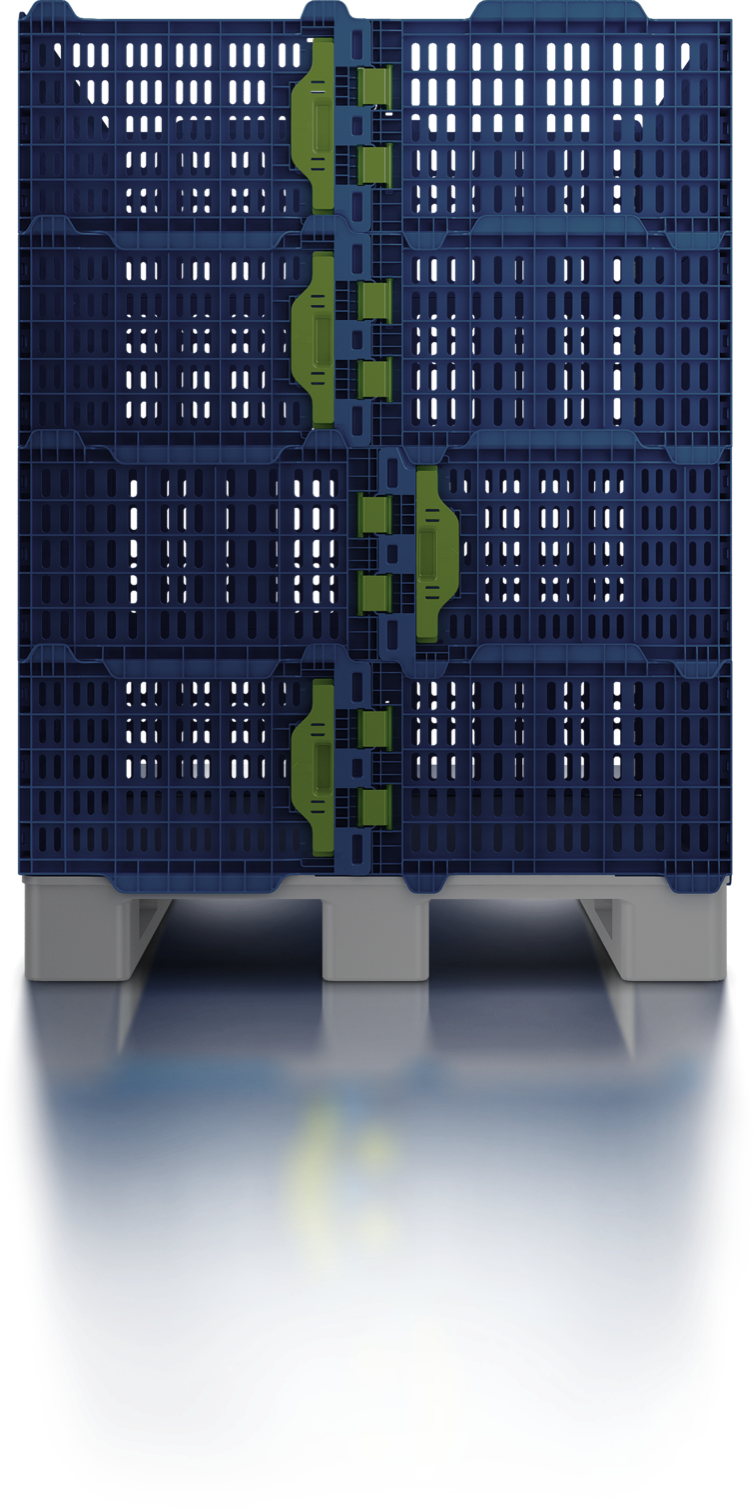

with pallet.With one 1200×1000 pallet only, Pallet Collars can be quickly transformed into a stable large-volume sleeve pack. The number of collars is adjustable as required, thus maximizing the use of storage space.

Non-sequential stacking

firm connection.

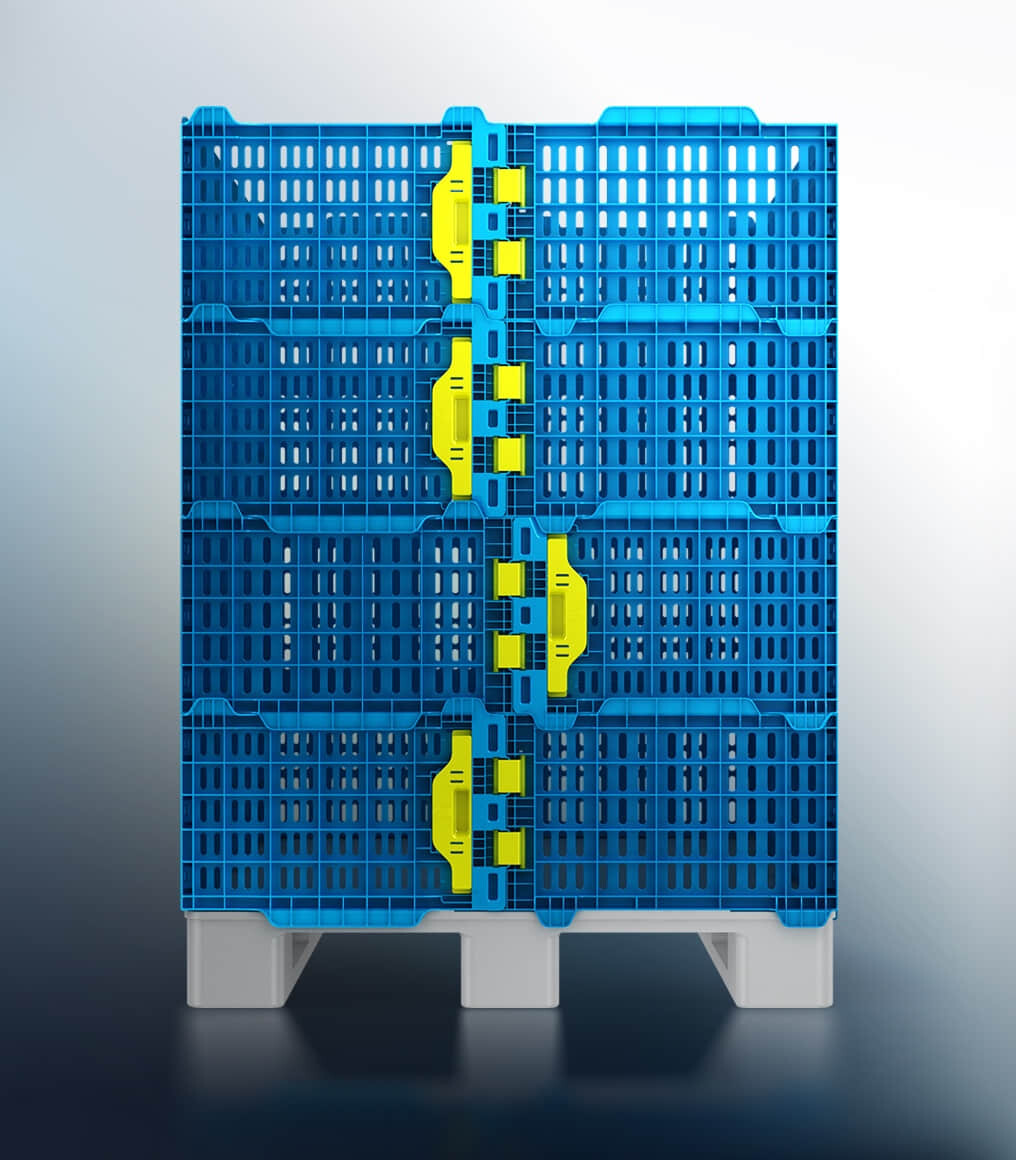

Steady stacking.Born for flexible stacking, HOREN’s Pallet Collar is vertically connected and locked with clips, without the need to distinguish between front and back. Easy-to-operate, they also help lower the labor intensity of operators.

Non-sequential

Stacking.Non-sequential stacking means Pallet Collar can fit together either way, so operators only need to make sure they are correctly attached to a pallet.

Firmly combined

with pallet.HOREN’s unique design ensures that Pallet Collar remains firmly on the pallet. Optional-use tie holes for fixing the collars to the pallet also help prevent separation.

Maximum space

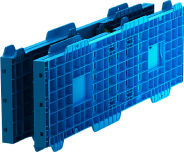

utilization.HOREN’s Pallet Collar is with a ultra-high folding ratio of 9:1. For each collar attached to a pallet, 8 pieces can be folded and loaded inside – equivalent to 11% of the erected storage space. This makes it easy for return transport, without any more disposable packaging materials.

Unique hinge.Side panels are connected with integrated hinges instead of traditional bolts, which makes folding and flipping more flexible and reduces the number of assembly parts. And thanks to its high strength and low assembly requirements, the hinge cuts the space of folded and saves return logistics costs.

Innovative

occlusion.The innovative H-shaped occlusion is designed to improve the tensile strength between side panels in full load, as well as structural stability and resistance to deformation after compression, prolonging service life and saving costs on maintenance.

User-friendly lock.The short side panels automatically lock after being erected. Operators can unlock with one hand, delivering a better operational experience. As the ease of use is greatly improved.

Pallet Collar

Unit-based combination

User-friendly lock

Ease to use

High folding ratio

Compatible with pallets

Suitable for light cargo

CHECK THE TECHNICAL DATA

Inquiry

All the data on this website is provided by HOREN unless otherwise stated.

*Full load: Only when the liquid density ≤ 1.35g/cm³.

*High reliability test: All tests are tested at HOREN’s standard labs in simulation of the conditions required by ISTA and ASTM.

*Traditional non-foldable IBC: Non-foldable plastic IBC tanks in general on the market with dimensions of 1200x1000x1145mm.

*Regular plastic foldable IBC: IBCs on the market under Asian and European standards and with dimensions of 1200x1000x1140mm and volume of around 1000L. Thus IBC OF330, with a volume of 1249L, is about 25% larger.

*Two-thirds: The volume of a folded IBC is approximately 1/3 of that when unfolded. So compared with a non-foldable container of the same size, 2/3 of the storage space is saved for return transport.

*Three-quarters: The volume of a folded IBC OF330 is approximately 1/4 of that when unfolded. So compared with a non-foldable container of the same size, 3/4 of the storage space is saved for return transport.

*Service life of up to 10 years: Measured in accordance with the limited conditions in HOREN’s standard labs.

*TE pin: Available upon request and purchase.

*Heater pad: Available upon request and purchase.

*7.6:1: The ratio of the volume of an erected KingKong RPC to that when folded is approximately 7.6:1.

*31%: Obtained upon measurement of multiple products under the same conditions of compression test in HOREN’s standard labs.

*No Crate Change: Goods stored in HOREN’s crates can be directly transported from farm or place of origin to market for display and sale, without the need to change to new crates.

*0.1%: In HOREN’s standard lab environment, 1000kg of 300,000-cP viscous liquid, after being discharging, leaves residues weighing <1kg.

*Hands-free: After RRS and liner are installed, no more manual operation is needed during the discharge process.

*Folding ratio 3:1: The ratio of the volume of an erected FLC KF975 to that when folded is approximately 3:1.