Accessories

OverviewLiner bags ValvesFittingsVideoSpecifications

Inquiry

Bag-in-boxBoth green and protectiveRe-use of IBCs only requires a new single liner, providing an easy solution for greener logistics packaging as well as great protection for special liquids. HOREN’s IBC liners reduce the discharge residue of liquid and cleaning costs, and is also much more hygienic.

IBC Liner.Hands-free filling.HOREN’s IBC liners are available in three types to meet the demands of different use scenarios and professions. Thanks to a professional and effective folding process, our liners boast the following advantages: easy installation and operation, hands-free filling, high efficiency, maximum volume, and high compatibility with filling devices.

Top offset filling.The filling spout is located on top and near the edge of the side panel.

Operation video

Operation video

Bottom central filling.The filling spout is located in the center of the bottom.

Operation video

Operation video

Top central filling.The filling spout is located in the center of the top.

Operation video

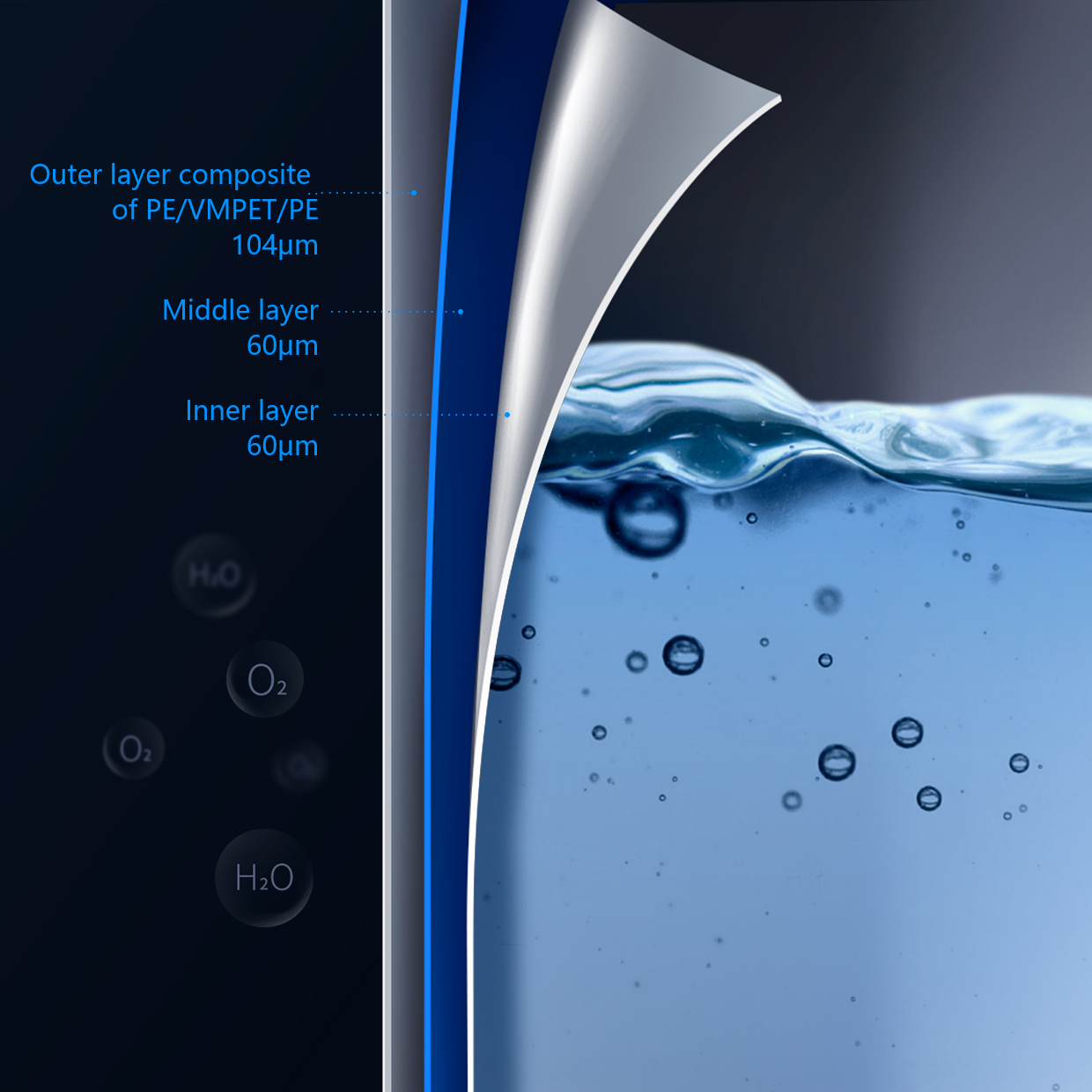

Operation videoFlexible bag & film types.Protect your products in harsh conditions.HOREN has customized a diverse of bag & film solutions to fulfill the professional applications of a wider range of customers. Our durable film structures deliver outstanding protection while preserving the quality.

Barrier film liner.

The liner’s aluminum film stops oxygen and water vapor from penetrating inside and causing oxidization or fermentation. It is suitable for the fruit and vegetable processing industry, liquid food, beverages, wines, as well as other volatile or oxidizable liquids.

Aseptic filling liner.

Our aluminum film (with 1-inch aseptic spout) liners are sterilized via irradiation at a dose of ≥15kGy for subsequent aseptic filling (also available by liners with high temperature sterilizable roplug valves or butterfly valves after high temperature disinfection). They are suitable for liquids such as jam, fruit juice concentrate, fruit pulp, and vegetable juice.

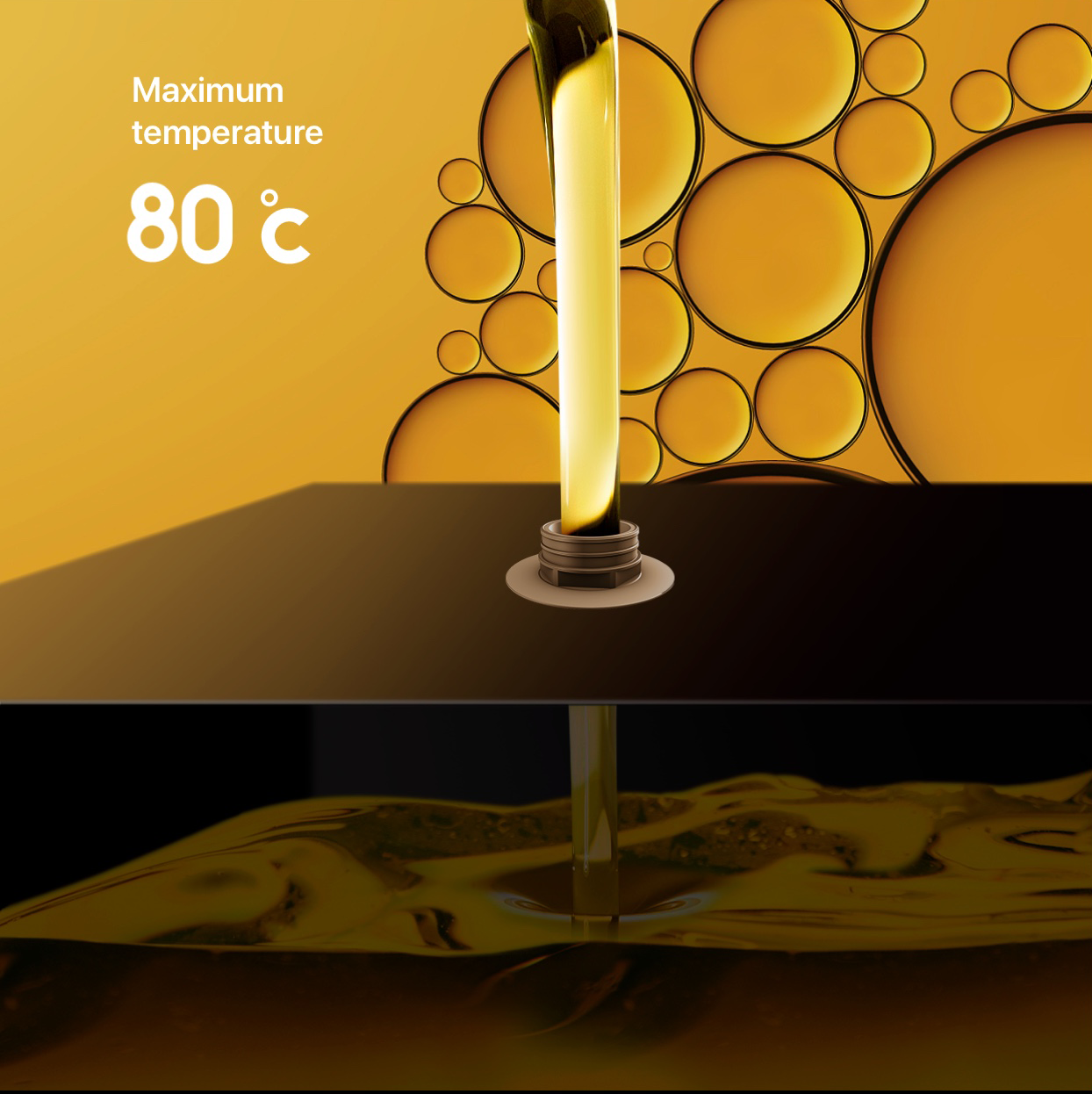

High-temperature film liner.

Our bespoke high-temperature liners offer better thermal structural stability under the harsh conditions of high-temperature filling at ≤80℃, coupled with safer and smoother discharge. When installed in standard IBCs, the liners can be widely applied to the high-temperature discharge of most oils, resins, and soybean oil.

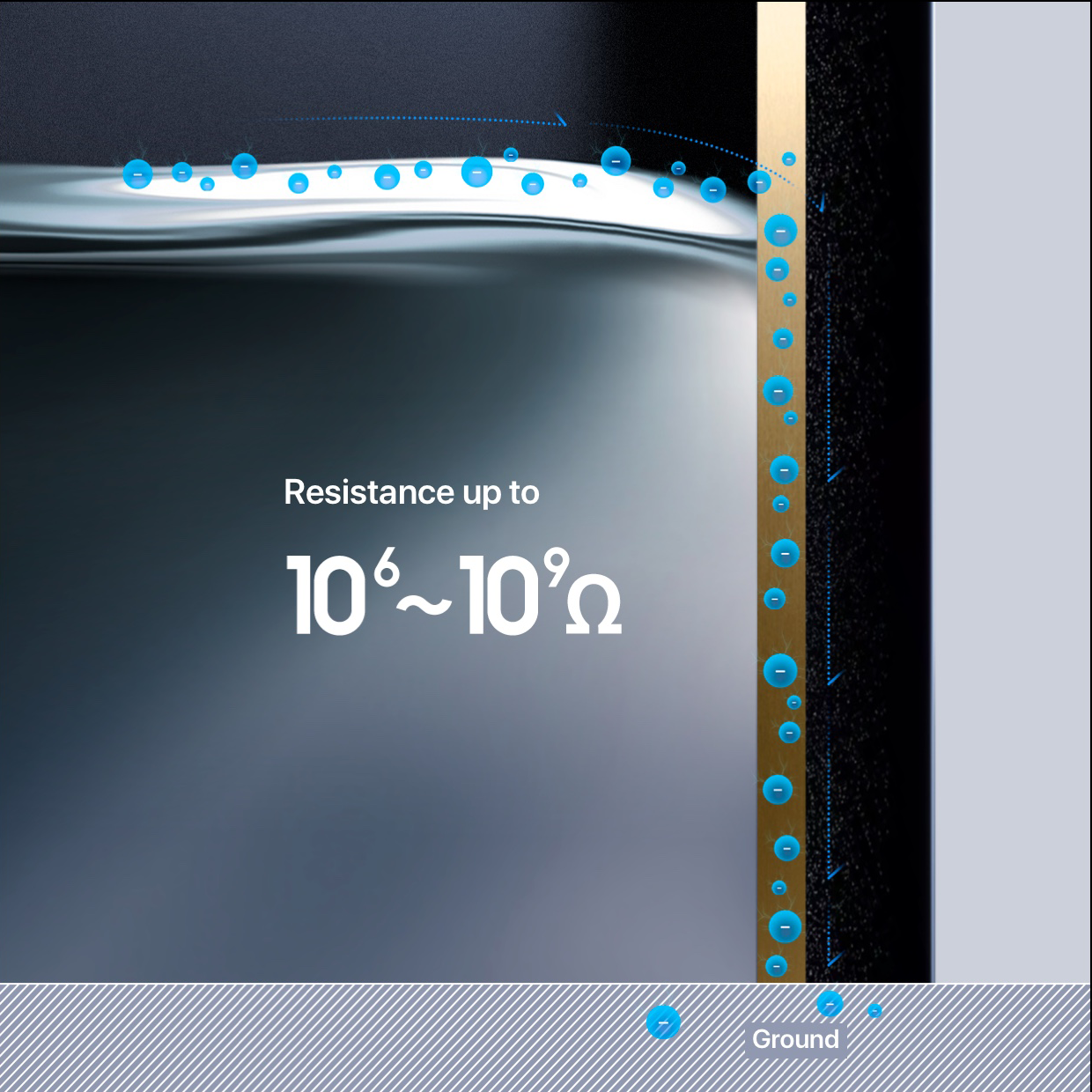

Antistatic film liner.

Antistatic liners feature special antistatic materials, to ensure a resistance value between 10⁶Ω and 10⁹Ω; together with antistatic IBCs, they provide a widely applicable solution to the transport needs of non-waterborne resins and oil-based paints in the coating industry.

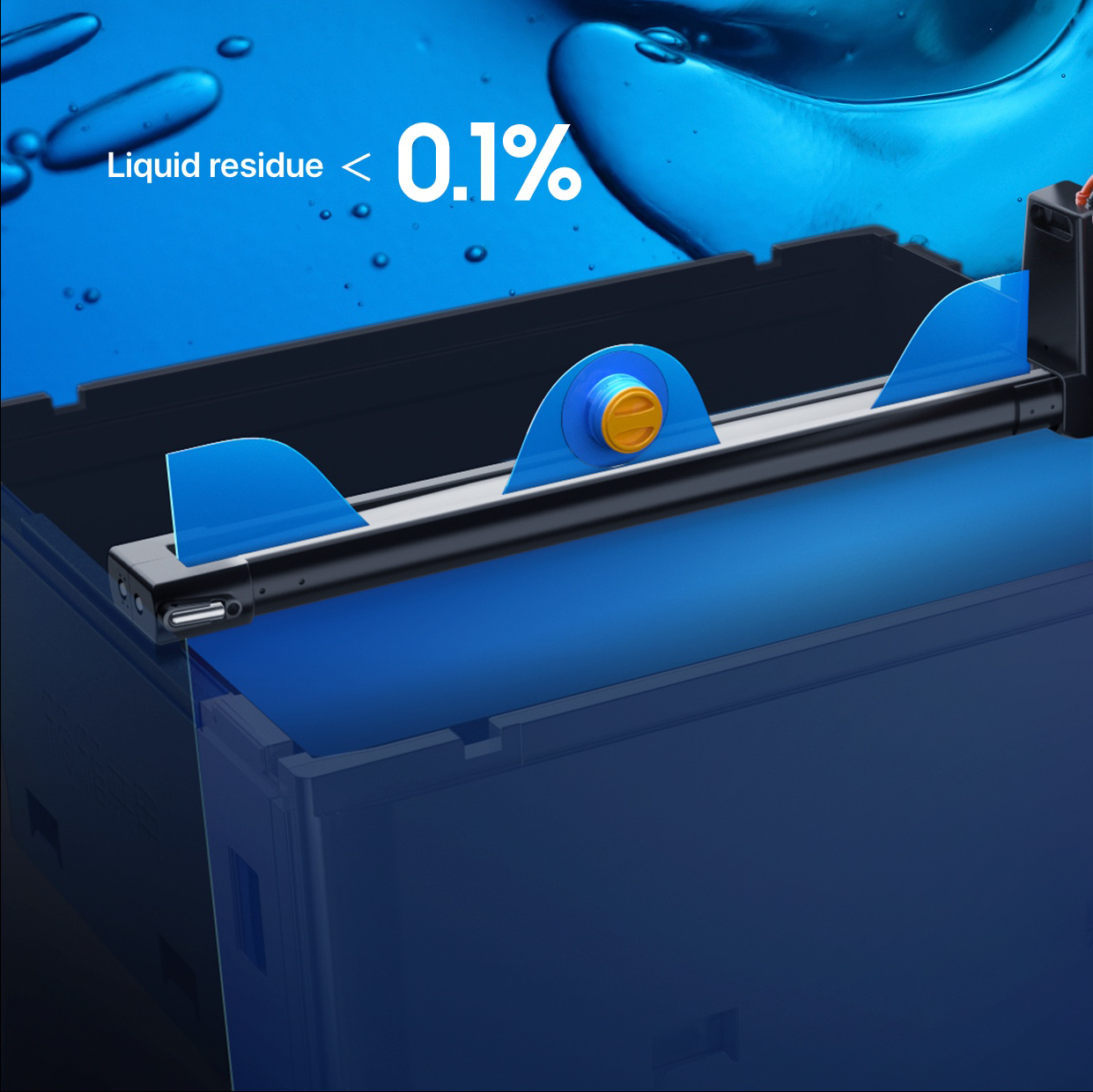

RRS specialized liner

Our low-residue liners are tailored for viscous liquids. Coupled with the Residue Reduction System (RRS), they can reduce liquid residues to below 0.1%*.

High security.Well-proven safety in multiple tests.To ensure the safety and reliability of the BIB solution, HOREN has established a reliability testing center. Prior to mass production, all products must undergo vibration tests, impact tests and drops that simulate the conditions of maritime, road and rail transportation in strict accordance with the standards of the International Safe Transit Association (ISTA). HOREN’s products have also been certified by the FDA, complying with the packaging standards of the food industry.

View parameters

Food-grade filling& discharging accessories.To cater to the different filling and discharging needs of customers, we provide simple filling spouts in four specifications: 1”, 2”, 3”, and 4”, as well as DN50 valves such as Pullplug, Roplug PC, Cutter Membrane and Butterfly.

Filling spouts.

1″Aseptic

1″Aseptic 1″Aseptic

1″Aseptic 2″F-Screw

2″F-Screw 2″F-Screw

2″F-Screw 3″F-Screw

3″F-Screw 3″F-Screw

3″F-Screw 3″M-Screw(For Emulsion)

3″M-Screw(For Emulsion) 3″M-Screw(For Emulsion)

3″M-Screw(For Emulsion) 4″M-Screw(For Emulsion)

4″M-Screw(For Emulsion) 4″M-Screw(For Emulsion)

4″M-Screw(For Emulsion)

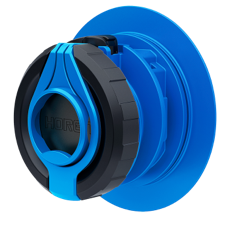

DN50 discharge valves.

Roplug PC

Roplug PC Roplug PC

Roplug PC Cutter Membrane Valve

Cutter Membrane Valve Cutter Membrane Valve

Cutter Membrane Valve Pullplug Valve

Pullplug Valve Pullplug Valve

Pullplug Valve Butterfly Valve

Butterfly Valve Butterfly Valve

Butterfly Valve

Roplug PC Valve is assembled by body and gland, integrating with a unique full-flow valve, which ensures large flow and fast discharge. It can also be sterilized by high temperature steam or γ-radiation to avoid secondary pollution during filling or multiple discharges. Steam at 0.2Mpa and below 120℃ for up to 20min; steam at 0.3Mpa and below 130℃ for up to 5min.

Integrated gland,full bore, large flow, simple operation, high efficiency performance, suitable for one-time discharge.

The Butterfly valve features a housing made of new materials and free from BPA,which is safer and healthier.The dual positioning seal ring assembly technology bring better sealing performance to the valve. It can also be sterilized by high temperature steam or y-radiation to avoid secondary pollution during flling or multiple discharges.Steam at 0.2Mpa and below 120℃ for up to 20min; steam at 0. 3Mpa and below 130℃ for up to 5min.

The Pullplug valve is the most compact bullt-in valve,non-steamable.Its integrated assembly with gland and a foldable handle,makes it asy to weld gland and liner and assemble the valve body in batches. The full-flow valve maximizes the flow rate,and is also tamper-evident.

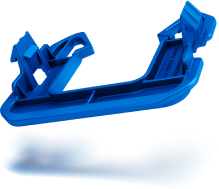

Plastic accessories.HOREN supplies plastic accessories are tailor-made for the BIB solution to ensure discharge stability and lid safety. These accessories include valve clamps, tamper-evident (TE) pins, valve blocks, etc.

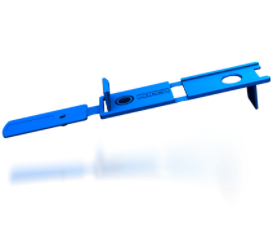

Disposable side push clip.It is adapted to DN50 valves, including pullplug, cutter membrane and butterfly valves, and can be installed on most of the IBCs on the market, simple operation and strong adaptability.

Returnable side push clip.It can be integrated with IBC’s sump, and is adapted to cutter membrane gland with a threaded fixing ring. Returnable and reusable.

TE Pin.All HOREN’s IBC lids can be fitted with TE pins to prevent unauthorized access to contents and ensure safe transportation.

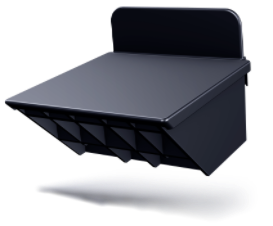

Valve block.Specially designed to block the bottom discharge sump when your product is pumped and discharged from the upper spout.

Family of all accessories.Ordinary yet helpful.HOREN provides an integrated portfolio of all accessories tailored to different scenarios. From standard parts to tailored offerings, from metal, to plastic and other materials, our products offer stable performance and simple operation, and are suitable for most of the non-hazardous chemical industries.

Our clients

All the data on this website is provided by HOREN unless otherwise stated.

*Full load: Only when the liquid density ≤ 1.35g/cm³.

*High reliability test: All tests are tested at HOREN’s standard labs in simulation of the conditions required by ISTA and ASTM.

*Traditional non-foldable IBC: Non-foldable plastic IBC tanks in general on the market with dimensions of 1200x1000x1145mm.

*Regular plastic foldable IBC: IBCs on the market under Asian and European standards and with dimensions of 1200x1000x1140mm and volume of around 1000L. Thus IBC OF330, with a volume of 1249L, is about 25% larger.

*Two-thirds: The volume of a folded IBC is approximately 1/3 of that when unfolded. So compared with a non-foldable container of the same size, 2/3 of the storage space is saved for return transport.

*Three-quarters: The volume of a folded IBC OF330 is approximately 1/4 of that when unfolded. So compared with a non-foldable container of the same size, 3/4 of the storage space is saved for return transport.

*Service life of up to 10 years: Measured in accordance with the limited conditions in HOREN’s standard labs.

*TE pin: Available upon request and purchase.

*Heater pad: Available upon request and purchase.

*7.6:1: The ratio of the volume of an erected KingKong RPC to that when folded is approximately 7.6:1.

*31%: Obtained upon measurement of multiple products under the same conditions of compression test in HOREN’s standard labs.

*No Crate Change: Goods stored in HOREN’s crates can be directly transported from farm or place of origin to market for display and sale, without the need to change to new crates.

*0.1%: In HOREN’s standard lab environment, 1000kg of 300,000-cP viscous liquid, after being discharging, leaves residues weighing <1kg.

*Hands-free: After RRS and liner are installed, no more manual operation is needed during the discharge process.

*Folding ratio 3:1: The ratio of the volume of an erected FLC KF975 to that when folded is approximately 3:1.